8

2 Installation

2.1 Caution

Please pay special attention to the following:

The cable between servo drive and servo motor should stay relaxed, not tense.

If the cable between servo drive and servo motor is more than 20 meters, please

Strengthen UVW connection and encoder connection.

When the servo driver is fixed, the installation direction must be in accordance with the regulations, and each fixed screw must be locked.

For the determination of concentric with the servo motor shaft and equipment shaft, to

prevent the radial stress when motor running.

Four fixed screws of the servo motor must be locked according to the prescribed torque.

In order to make the cooling effect better, when install AC servo drives, the upper and lower, left and right and adjacent items and baffle

(wall) must keep enough space, otherwise it will cause fault.

When the servo driver is installed, it can not be dumped. The air suction and exhaust holes are not blocked, otherwise, the fault can be

caused.

2.2 Storage ambient conditions

Please put the product in its packing box before installation. If the drive is not used, in order to enable the product to meet the company's

scope of warranty and future maintenance, be sure to pay attention to the following conditions:

2.3 Installation ambient conditions

2.3.1 EA100 servo drive using ambient conditions:

Ite

m

Description

Dust and gas

No dust, free of corrosive gas or liquid.

Ambient humidity

Relative humidity 20%

~

90%

(

no condensation

)

Ambient temperature

0

℃~

+45

℃

Vibration

Below 4.9m/s²

Impact

Below 49m/s²

Elevation

Below 1000m,please derating above 1000m

2.3.2 SER series servo motor using ambient conditions:

Ite

m

Description

Ambient humidity

Relative humidity20%

~

80% (no condensation)

Ambient temperature

0

℃~

+40

℃

Vibration

Below 4.9m/s²

Impact

Below 49m/s²

Elevation

Below 1000m,please derating above 1000m

Do not use motor in closed ambient. Closed ambient will lead to high temperature of motor, shorten the service life.

2.3.3 Other caution

In addition to the above ambient conditions, regardless of the drive or motor, when selecting the installation site, please observe the

following precautions,otherwise, may make the product can not meet the company's warranty coverage and future maintenance:

No high temperature.

No water drops, steam, dust and oil dust.

No corrosive or flammable gas or liquid.

No floating fiber or metal particles.

Installation base shall be solid and free from vibration.

No electromagnetic interference and away from interference source.

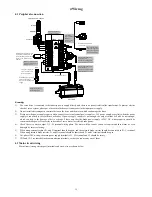

2.4 Servo Drive Installation Direction and Space

Servo drive and servo motor appearance size and weight specifications, please refer to the chapter 10.

2.4.1 Method

Please ensure the installation direction and walls are vertical. To use natural convection or fan for cooling of the servo drive. Through the

mounting hole, the servo driver is firmly fixed on the mounting surface.

When installing, please turn the servo drive front (the operator's actual mounting face) to the operator, and make it perpendicular to the wall.

2.4.2 Cooling

Item

Description

Storage temperature

-20

℃~

+65

℃(

high temperature: 80

℃

72hours

)

Storage humidity

Relative humidity of 0% to 95% with no condensation

Vibration

Below 49m/s²

Impact

Below 490m/s²