Assembly

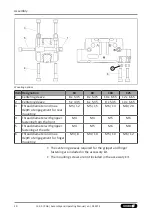

4.1.2.1 Air purge connection

For applications in dirty environments, the service life can be

increased by using air purge of

0.5 bar (max. 1 bar permitted)

at

one of the two S connections.

NOTE

Note that use under extreme ambient conditions (e.g. coolant

range, with casting or abrasive dust) can significantly reduce the

service life of these units and we cannot accept any liability for

this.

4.2 Mounting the sensor

NOTE

Observe the assembly and operating manual of the sensor for

mounting and connecting.

The product is prepared for the use of sensors.

• For the exact type designations of suitable sensors, please see

• For technical data for the suitable sensors, see assembly and

operating manual and catalog datasheet.

– The assembly and operating manual and catalog datasheet

are included in the scope of delivery for the sensors and are

available at schunk.com.

• Information on handling sensors is available at schunk.com or

from SCHUNK contact persons.

4.2.1 Overview of sensors

Designation

PGB

64

80

100

125

Inductive proximity switch IN 80

X

X

X

Magnetic switch MMS 22

X

X

X

X

Programmable magnetic switch MMS 22-PI2

X

X

X

X

Programmable magnetic switch MMS-P 22

X

X

X

X

Programmable magnetic switch MMS 22-PI1

X

X

X

X

Magnetic switch MMS 22-IOL

X

X

X

X

Analog position sensor APS-Z80

X

X

X

Reed switch RMS 80

X

X

X

Flexible position sensor FPS-S M8

X

X

X

Analog position sensor APS-M1

X

X

X

23

13.00 | PGB | Assembly and Operating Manual | en | 389275

Содержание PGB

Страница 1: ...Original operating manual Assembly and Operating Manual PGB 2 finger parallel gripper with center bore...

Страница 50: ......

Страница 51: ......