1.0 SAFETY INFORMATION

!

WARNING

(SEE WARNINGS IN REGARD TO DUCTWORK)

Do not install this unit in manufactured (mobile) homes. Improper installation

is more likely in manufactured housing due to ductwork material, size, loca-

tion, and arrangement. Installations in manufactured housing can cause a fire

resulting in property damage, personal injury or death.

EXCEPTION: Manufactured housing installations are approved only with docu-

mentation by a recognized inspection authority that the installation has been

made in compliance with the instructions and all warnings have been

observed.

!

WARNING

(SEE SECTION 3.2: VERTICAL UPFLOW & HORIZONTAL LEFT)

If unit is to be installed without an indoor coil, return air duct, or plenum, it must

not be installed directly over combustible material. If installed without an indoor

coil with a return duct or plenum, the air plenum or duct must have a solid sheet

metal bottom with no return air openings, registers or flexible air ducts located

directly under the unit. Exposing combustible material to the return opening of

an upflow unit without an indoor coil can cause a fire resulting in property dam-

age, personal injury or death.

!

WARNING

(SEE SECTION 13.7: ECM CONTROL MODULE REPLACEMENT)

Always have 240 volt power turned off to the furnace before attempting any

replacement of the motor or control module. Failure to do so may result in seri-

ous equipment damage, personal injury or death.

!

WARNING

(SEE SECTION 4.0: ELECTRICAL WIRING)

Disconnect all power to unit before installing or servicing. More than one

disconnect switch may be required to de-energize the equipment.

Hazardous voltage can cause severe personal injury or death.

Continued on next page

➜

!

WARNING

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the home causing property damage. Fumes and

odors from toxic, volatile or flammable chemicals, as well as automobile

exhaust and carbon monoxide (CO), can be drawn into the living space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage stor-

age areas - all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depres-

surization of the space and possible migration of combustion byproducts

including carbon monoxide into the living space.

3

!

WARNING

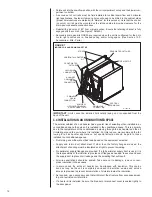

The first 36 inches of supply air plenum and ductwork must be constructed of

sheet metal as required by NFPA 90B. The supply air plenum or duct must

have a solid sheet metal bottom directly under the unit with no openings, reg-

isters or flexible air ducts located in it. If flexible supply air ducts are used they

may be located only in the vertical walls of a rectangular plenum, a minimum

of 6 inches from the solid bottom. Metal plenum or duct may be connected to

the combustible floor base, if not, it must be connected to the unit supply duct

flanges such that combustible floor or other combustible material is not

exposed to the supply air opening from the downflow unit. Exposing com-

bustible (non-metal) material to the supply opening of a downflow unit can

cause a fire resulting in property damage, personal injury or death.

Exceptions to downflow warnings:

• Installations on concrete floor slab with supply air plenum and ductwork

completely encased in not less than 2 inches of concrete (See NFPA 90B).

Содержание RHPL-HM2421JC

Страница 37: ...37 FIGURE 29 AIR HANDLER EQUIPPED WITH Serial Communication WIRING DIAGRAM...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40 CM 0411...