33

13.5 LUBRICATION

The blower motor sleeve bearings are pre-lubricated by the motor manufacturer and do

not have oiling ports. Motor should be run for an indefinite period of time without addi-

tional lubrication.

13.6 BLOWER ASSEMBLY REMOVAL AND REPLACEMENT

Removing the blower assembly is not required for normal service and maintenance.

Removal is necessary for replacement of components such as motor and/or blower

wheel. After extended use, removal of the blower assembly may become necessary for

a thorough cleaning of the blower motor and wheel.

• Mark field power supply wiring (for replacement) attached to terminal block or circuit

breaker(s) on blower assembly. Remove wiring from terminal block or circuit break-

er(s).

• Mark low voltage control wiring (for replacement) where attached to unit control termi-

nals on left side of blower housing.

• Remove a screw holding blower assembly to front channel of cabinet and pull blower

assembly from cabinet.

• To replace blower assembly, slide blower assembly into blower deck. Make sure

blower assembly engages lances in deck properly. If assembly hangs up, check to

make sure top and bottom are lined up in proper locations.

• Slide blower assembly to back of cabinet and make sure it is completely engaged.

• Replace two screws holding blower assembly to front channel of cabinet. Take care

not to strip screws, just snug into place.

• Replace low voltage control wiring with wire nuts and make sure wiring is to wiring

diagram and a good connection has been made.

• Replace field power wiring to terminal block or circuit breaker(s) on control area of

blower assembly. Make sure wires are replaced as they were, check wiring diagram if

necessary. Tighten supply power wiring securely to terminals lugs.

• Make sure wiring is within cabinet and will not interfere with access door. Make sure

proper separation between low voltage control wiring and field power wiring has been

maintained.

• Replace blower assembly control access panel before energizing equipment.

13.7 MOTOR REPLACEMENT

With the blower assembly removed, the indoor blower motor can be removed and

replaced using the following procedure:

• Remove motor leads from the motor high and low voltage plugs. Note the lead loca-

tions for ease of re-assembly.

• Loosen the set screw holding the blower wheel onto the motor shaft. The shaft

extends through the blower hub so that a wrench can be used on the extended shaft

to break the shaft loose if necessary. Be careful not to damage the shaft. Use a

wheel puller on the groove in the hub if necessary.

• Loosen the bolt holding the wire motor band around the motor shell and pull the

motor from the motor mount. Note the motor position in the mount for re-assembly.

• To re-assemble, insert the motor shaft through the hub in the blower wheel and orient

the motor to original position.

• For proper motor cooling, it is important that the motor be mounted the same as the

original, as far into the blower as practical.

• The dimension from the face of the motor end plate (shaft end) to the edge of the

motor mount belly band should be:

DIMENSION

TONNAGE

CABINET SIZE

1

1

/

2

"

2

21

1

1

/

2

"

3

21

2

7

/

8

"

4

24

2

7

/

8

"

5

24

!

WARNING

If removal of the blower assembly is required, all disconnect switches supply-

ing power to the airhandler must be de-energized and locked (if not in sight of

unit) so the field power wires can be safely removed from the blower assem-

bly. Failure to do so can cause electrical shock resulting in personal injury or

death.

Содержание RHPL-HM2421JC

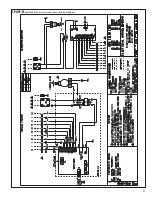

Страница 37: ...37 FIGURE 29 AIR HANDLER EQUIPPED WITH Serial Communication WIRING DIAGRAM...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40 CM 0411...