21

Profile D – Dry Climate profile

The Dry Climate profile is configured for areas that require little to no additional dehu-

midification.

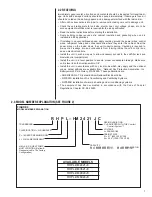

5.11 CONVENTIONAL 24VAC THERMOSTAT CONTROL WIRING

The (-)PRL series of heat pumps allow the installer to use conventional 24VAC control

wiring and a conventional thermostat for proper unit operation.

IMPORTANT: The preferred method of unit installation and operation is by the Comfort

Control

2

System™, which allows access to the fault history of the system. This diagnos-

tic information is not available when the (-)PRL unit is using a conventional thermostat.

Reference section 5.1 Comfort Control

2

System™ Control Wiring.

Thermostat control wiring requires a minimum of eight (8) wires for proper unit operation:

R – 24VAC

C – 24VAC common

G – Constant Fan

W1 – First stage electric heat

W2 – Second stage electric heat

Y1 – First stage operation

Y2 – Second stage operation

B – Heat pump operation

Optional wiring:

ODD – On demand humidification

NOTE: W1 and W2 may be jumpered together to energize all the electric heat when a

call for electric heat is received if warmer supply air temperature is desired.

NOTE: When using 24VAC thermostat control wiring, the serial communicating control

will ignore any inputs to Data wire 1 and Data wire 2.

IMPORTANT: Class 2 low voltage control wire should not be run in conduit with power

wiring and must be separated from power wiring, unless Class 1 wire of proper voltage

rating is used.

Low voltage control wiring should be 18 AWG color-coded (105°C minimum). For

lengths longer than 100 ft., 16 AWG wire should be used.

Low voltage control connections are made by extending wires from top of air handler

using wire nuts.

See wiring diagrams attached to indoor and outdoor sections to be connected

Do not leave excess field control wiring inside unit, pull excess control wire to outside of

unit and provide strain relief for field wiring on inside of cabinet at point wiring penetrates

cabinet.

Make sure, after installation, separation of control wiring and power wiring has been

maintained.

5.12 USING THE ON-BOARD LED TO DETERMINE BLOWER CFM

The CFM LED indicates blower output by flashing one (1) flash for every 100 CFM of air-

flow. The LED will pause 1/10 second between each flash.

5.13 COOLING AIRFLOW SETTINGS

FIGURE 18

DIP SWITCH SETTING FOR COOLING AIRFLOW

8

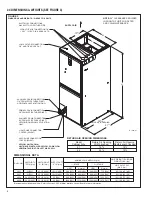

6.2 Serial Communications Control

The (-)HPL series air handler control, figure X.X, has the following features:

•

An automotive-style ATC blade fuse for transformer protection (3 amp).

•

An on-board LED to indicate blower CFM.

•

An RJ-11 port for use with a diagnostic tool.

•

Inputs for field installed supply and return air temperature sensors (available in kit RXHT-

A01)

•

DIP switches for airflow adjustments

IMPORTANT:

A diagnostic tool can be used to display any air handler diagnostic codes.

However, no system changes are permitted. Any system changes MUST be done via the DIP

switches.

Installation Verification

•

24V AC power on R&C must be present at the control for the air handler to operate

•

Line voltage must be present at the control for indoor blower operation.

•

The control wires must be connected to a conventional 24VAC thermostat for proper

operation.

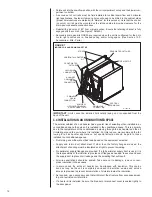

6.3 Using the On-Board LED to Determine Blower CFM

The (-)HPL interface board LED indicates blower output by flashing one (1) second for every

100 CFM of airflow. The LED will pause 1/10 second between each flash. After the blower

CFM has been displayed, the LED will illuminate dimly for 10 seconds before repeating the

sequence. (See Table 1.)

6.4 Cooling Airflow Settings

Figure X – DIP switch setting for cooling airflow

CONVENTIONAL THERMOST

A

T WIRING

On Delay

Air Handler

Delay Duration

(second)

% Rated Airflow

Off Delay (seconds)

RHPL-HM2421

150

88

60

RHPL-HM3621

150

88

60

RHPL-HM4824

150

88

60

RHPL-HM6024

150

88

60

Содержание RHPL-HM2421JC

Страница 37: ...37 FIGURE 29 AIR HANDLER EQUIPPED WITH Serial Communication WIRING DIAGRAM...

Страница 38: ...38...

Страница 39: ...39...

Страница 40: ...40 CM 0411...