0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 23

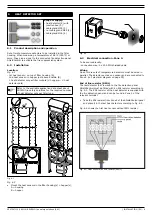

13.7 Solenoid valve

13.8 FlameShield

13.9 System control panel SCP

13.10 Final

The entire system including the ShieldControl panel must be

tested periodically in accordance with the national fire

protection association requirements or the authorities having

local jurisdiction.

The indicated maintenance intervals can vary depending on the

specific working and ambient conditions. Therefore it is

recommended to perform the first general maintenance check

three months after commissioning and determine the future

frequency based on the state of the system after this period. In

any case the complete system must be checked at least once a

year.

•

Refer to the separate system components about method and

frequency of maintenance. Maintenance activities have been

summarized in the maintenance calendar below.

14.1 Maintenance calendar

The maintenance activities in the table below indicated by [*]

can be carried out by the user; other activities are strictly

reserved for well trained and authorized service personnel.

The post-fire procedure is strictly reserved to skilled and

authorised service engineers.

•

Carry out the post-fire procedure as written in paragraph

18.2 on page 25.

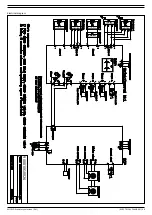

Refer to electrical diagram on page 29.

#

Check

OK

1.

Is the 3/2 solenoid valve mounted between

compressed air reducer (CAR kit) and filter?

2.

Is the solenoid electrically and pneumatically

correctly wired? When the solenoid is

disconnected from power, the air of the

compressed air tanks of the filter system should

be released.

3.

Is the solenoid functionally tested after a fire

test alarm in the complete system set up?

#

Check

OK

1.

Are FlameShield modules undamaged?

2.

Is the correct number of FlameShield modules

being installed?

3.

Are the FlameShield modules placed at the

correct position?

4.

Are the FlameShield modules pushed back to

the middle stop of the mounting bracket to

secure a 10° downwards release angle?

5.

Are all nuts and bolts well tightened?

6.

Are the cables tension free, well guided and

fixed by the cable glands?

7.

Are the cable glands well tightened?

8.

Is the internal wiring/electrical activation

checked by measuring resistance over the

internal heating device of the FlameShield with

a current less than 5 mA? The resistance must

be 2 ohm.

9.

Are, in combination with ShieldControl 5k1, the

EOL resistor-diodes of 5k1 placed in each

junction box and the FlameShield connected to

output 2, 3 or 4?

#

Check

OK

1.

Is the system control panel SCP correctly

connected to the ShieldControl panel and

peripheral equipment?

2.

Is the system control panel SCP functionally

tested on a test alarm and performed expected

actions (fan stops, sliding valves close, 3/2

solenoid opens)?

#

Check

OK

1.

After all functional testing, reset all detectors

and panels. When no alarm signals are visible,

connect the FlameShield modules. Make sure

that ShieldControl is on

RUN

.

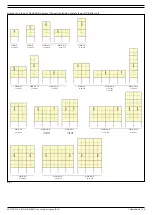

14

MAINTENANCE

Frequency

Component

* Ref.

par.

page

Regularly,

depending on

intensity of use

Heat detectors

* 6.5

Spark detectors

* 7.5

Smoke detector

* 8.5

Whenever dirty

ShieldControl panel * 5.5

Every 6 months

Sliding valves

At least every 12

months

FlameShield

Every year

ShieldControl panel

Every 4 years

ShieldControl panel

Every 10 years

FlameShield

15

POST-FIRE PROCEDURE

16

ELECTRICAL DIAGRAM

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...