0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 19

11.1 Product description and operation

FlameShield

1

is a fire suppression generator designed to be

installed directly into the filter system. FlameShield is activated

by the ShieldControl fire detection panel 5 seconds after a fire

alarm.

The FlameShield is designed to suppress or extinguish filter fires

of EN 2 Class A and NFPA 10 Class A (normal or solid

combustible material in Plymovent filters).

In 5 to 10 seconds, the filter volume closed by the sliding valves

is filled with a potassium aerosol. This material reacts with the

free radicals in the flame. The free radicals react with the

aerosol instead of the fuel and the chain reaction is stopped

immediately. The residue is a negligible amount of harmless and

stable potassium hydroxide salt (KOH). This reaction also uses

energy from the fire.

After activation the aerosol remains active for at least 30

minutes, which also prevents the fire from starting up again.

11.1.1 Transport and storage

To avoid damage, the following conditions for transport and

storage should be adhered to.

- Do not drop.

- Store between -50 and +100°C (-58 and +212°F).

- Relative humidity during transport and storage: max. 98%.

If FlameShield is stored in accordance with the above-

mentioned conditions, shelf life of the aerosol generator is 15

years.

11.2 Installation

•

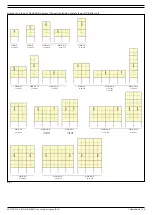

Refer to Fig. I on page 28 for the required number, type

2

and

position of FlameShield aerosol generator in MDB filter

system.

Final installation position of FlameShield must be as follows.

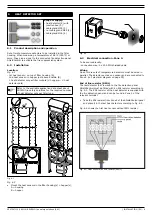

Fig. 11.1

A Filter cartridge

B Junction box

C Framework MDB

D Mounting bracket FlameShield

E FlameShield module

Fig. 11.1

To install the FlameShield module(s), proceed as follows.

Assemble the mounting bracket (part A + B).

•

Drill 2 x 2 holes in the framework of the MDB housing in

accordance with the supplied drilling template.

•

Mount the junction box (C) along with the mounting bracket

using the supplied bolts, washers and nuts.

•

Place a cable gland (F) in the junction box using one of the

knock-out cable entries.

•

Guide the cable through the cable gland into the junction

box.

•

Place the FlameShield module (E) in the bracket. Make sure

to push the generator to the middle stop (D) to ensure the

correct flow direction of 10°.

•

Fasten tightly.

11

FLAMESHIELD

Scope of supply:

- aerosol generator (200

or 500 g)

- mounting bracket (two-

piece)

- junction box

- metal cable gland

- plastic cable gland (2)

- mounting material

1. FlameShield is the name used by Plymovent for the use of FirePro

aerosol generators in Plymovent filter systems. FirePro is a product

of Celanova Ltd. Listing and certifications are registered under the

name FirePro.

2. Number and type of FlameShield aerosol fire extinguishing

generators has been calculated by certified personnel in conformity

with BRL-KZ 3003 and NFPA 2010, based on filter class A, E, safety

factor 1.3 and min. concentration of 55.29 g/m² effective

component.

WARNING

Failure to use the correct number, type and position of

the FlameShield generators will prejudice the effective

fire response.

Use one of the predrilled holes in the junction box

housing to mount it. The box can be mounted using

only one mounting point.

C

A

B

MDB

A

D

E

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

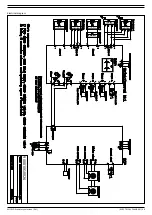

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...