0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 20

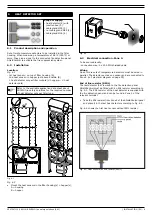

Fig. 11.2

11.3 Electrical connection

To be sourced locally:

- connection wire: 5 x 20 AWG

Connection to ShieldControl 5k1

•

Place an EOL diode supplied with the ShieldControl in the

junction box in series over each FlameShield, in accordance

with the electrical diagram on page 29.

11.4 Post installation checks

Before performing the functional test, check the following

mounting instructions.

•

Wiring from and to the ShieldControl.

•

EOL resistor-diode in junction box.

•

Correct position and flow angle (10°) of FlameShield

generator.

•

Tightening of bolts and nuts.

11.5 Functional test

A functional test can be done in two ways:

- by a simulation

- true functional test

11.5.1 Simulation

Two heat resistant wires are connected to an internal metal

spiral activator in the FlameShield generator. The spiral is

heated by the current and starts an exothermic chemical

reaction that releases the aerosol. The minimum amount of

energy needed to start the reaction is supplied by 12V/0.8 A

during 3-4 seconds.

The internal wiring of the activator can be inspected by

measuring the internal ohm resistance of 2 ohm +/- 0.2 ohm

with an ohm meter with a current less than 5 mA. This

inspection can be done in the junction box mounted on the

outside of the filter by measuring the ohm resistance over the

heat resistant wires.

•

Check electrical activation of the FlameShield modules

according to the above instruction.

11.5.2 True functional test

A true functional check can be done by replacing the

FlameShield module with the detonation simulator supplied and

create a fire condition (e.g. by removing one of the spark

detectors). After fire alarm the detonation simulator will be

activated showing a small flash.

•

Perform a true functional test as described above.

•

Reset activated detector (refer to relevant chapter).

•

Press the

SYSTEM RESET

button on the ShieldControl panel.

•

Reconnect the FlameShield module(s).

11.6 Maintenance

During the lifespan of FlameShield, the generators must be

inspected periodically in accordance with the national fire

protection association requirements or the authorities having

local jurisdiction.

Due to their chemical composition and characteristics, the

FlameShield generators do not require any inspection and

maintenance during their lifespan.

E

D

C

F

B

A

MDB

WARNING

Use Personal Protective Equipment (PPE) to protect

from exposure to sparks.

WARNING

Keep away from inflammable material and do not hold

in the hand.

Component

Action

Frequency:

at least

every 12

months

every 10

years

Metal holder

Check for damage, corrosion

and correct position.

X

Support bracket Check for damage, corrosion

and correct position.

X

System wiring

connections and

circuit

Check proper wiring and

circuit.

X

FlameShield

internal

activation

Check internal activation;

X

Aerosol

generator

REPLACE. X

WARNING

When the filter installation with FlameShield

generators is placed in an area where it is exposed to

vibrations due to e.g. heavy machinery, more frequent

inspections are needed to secure correct positioning.

Put a sticker on the FlameShield generator(s) stating

the installation date and/or keep a log.

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

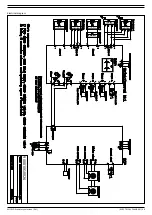

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...