0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 22

13.1 ShieldControl

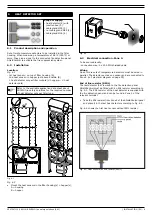

13.2 Heat detector set(s)

13.3 Spark detector set

13.4 Smoke detector

13.5 Manual call point and fire alarm sounder

13.6 Sliding valves

13

COMMISSIONING CHECKLIST

#

Check

OK

1.

Is the ShieldControl panel connected to a clean

electrical group or a group not subject to regular

power failures by other equipment?

2.

Is the panel placed in an environment without

excessive dust in line with IP 30 or otherwise

placed in a cabinet?

3.

Are all cables checked for correct connection in

accordance with the electrical diagram?

4.

Are the EOL resistors removed from the

terminals that are in use and placed in the

connected equipment?

5.

Are the cables well guided and fixed?

6.

Is a shielded cable being used for all detectors

as well as the manual call point?

7.

Is the ShieldControl 5k1 switched to

RUN

mode?

8.

No fault signals on the ShieldControl panels?

#

Check

OK

1.

Are the heat detectors placed on top inside the

filter housing and in the hopper just above the

dustbin?

2.

Number of heat detector sets = number of

hoppers?

3.

Are the heat detectors wired in parallel and

connected to Zone 2 of ShieldControl?

4.

Is an EOL resistor of 5k1 placed in the last heat

detector?

5.

Is each heat detector being functionally tested

by gently heating it with a heat gun or heat lamp

and alarm signal being monitored by

ShieldControl?

#

Check

OK

1.

Are the spark detectors placed face to face in the

filter outlet duct?

2.

Ensure that the spark detector is not mounted

on the bottom of the duct.

3.

Are the spark detectors shielded against any

light and holes sealed with metal foil? Do not use

duct tape since this may let through infrared

light.

4.

Are the spark detectors wired in parallel and

connected to Zone 1 of ShieldControl?

5.

Is the last spark detector in the circuit provided

with REOL of 5k1 in line with ShieldControl 5k1?

6.

Is the earth connection properly made?

7.

Are the lenses clean?

8.

Are the spark detectors being functionally tested

through exposure to daylight and the signal

being monitored by ShieldControl?

#

Check

OK

1.

Is the smoke detector placed in the filter outlet

duct?

2.

Is the mounting bracket correctly installed in

relation to the airflow?

3.

Is the smoke detector connected to Zone 3 of

ShieldControl?

4.

Is the smoke detector being functionally tested

by test spray? Is the signal being monitored by

ShieldControl?

#

Check

OK

1.

Are the manual call points marked or placed

close to the ShieldControl panel in order to avoid

confusion with the general manual alarm boxes

of the building?

2.

Is the REOL that was placed in the manual call

point in line with the ShieldControl 5k1?

3.

Are the fire alarm sounders placed close to the

ShieldControl panel and fitted with the correct

EOL resistor 5k1?

4.

Is the sounder set to your local tone?

5.

Is sound level set to the maximum?

6.

Is the manual call point being functionally tested

and monitored by the ShieldControl?

7.

Is the fire alarm sounder being tested and

activated by ShieldControl?

#

Check

OK

1.

Can the ductwork carry the weight of the sliding

valves? If not, make sure the duct is properly

supported.

2.

Are the sliding valves mounted straight and

tension-free in the duct? Tension on the housing

results in inadequate sealing and noise by

airflow.

3.

Are the sliding valves pneumatically and

electrically wired?

4.

Are the reed contacts of the sliding valves

connected to the system control panel SCP?

5.

Are sliding valves mounted indoors? If not, are

they adequately protected against precipitation,

such as rain and snow?

6.

Is the compressed air pressure for the sliding

valves 4-5 bar and the compressed air dry and

oil-free?

7.

Do the sliding valves close in 4-5 seconds? If

not, reduce or increase pressure.

8.

Are the pneumatic and electrical wiring guided

away from potential fire places like duct and

filter?

9.

Make sure that the compressed air feed of the

sliding valves is an independent line and not via

the compressed air for the cleaning of the filter.

10.

Are the sliding valves functionally tested after a

fire test alarm in the complete system set up?

11.

Do the sliding valves close when filter system is

shut down and open at filter start up?

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

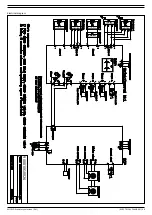

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...