0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 11

7.1

Product description and operation

Set of two infrared spark detectors. The spark detectors are

sensitive to the near IR light between 0.4 to 1.1 microns

wavelength.

When glowing particulate from the burning filter enters the field

of view of the detector, the detector responds by sending an

alarm to the ShieldControl fire detection panel.

7.2

Installation

Location:

- in filter outlet duct

- face to face (180° apart from each other) in the same vertical

plane

- min. 2,5x duct diameter from bend or branch

The spark detectors can be mounted without having access to

the inside of the duct. In this case you will need the supplied

insertion tool.

In case of a new or disconnected duct

allowing access to the

inside

, proceed as follows.

Make a hole Ø 38 mm (1.5 in.) in the duct using the supplied

hole saw.

•

Mount the flange (D) in the duct using the split washer (C),

washer (B) and nut (A).

•

Tighten washer and nut on the flange.

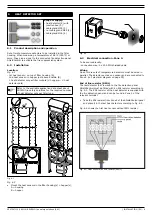

Fig. 7.1

In case of

no access to the inside

of the duct, proceed as

follows.

Make a hole Ø 38 mm (1.5 in.) in the duct using the supplied

hole saw.

•

Slip nut (B), washer (C) and split washer (D) on the insertion

tool (A) until the tool fits tightly on the flange (E). The nut

and washer should be loose on the shaft of the tool.

•

Push the flange completely through the hole in the duct and

insert the split washer by rotating it into the inside of the

duct.

•

Gently pull the flange back through the hole with the

insertion tool so it rests against the split washer inside the

duct.

•

Tighten washer and nut on the flange.

•

Remove the insertion tool by loosening the wing nut and

pulling straight back and twisting if required.

Fig. 7.2

Insert the spark detector lens (A) into the flange (C).

•

Fasten the detector using the supplied fixation screw (B).

•

Follow the same procedure for the second spark detector.

Fig. 7.3

7.3

Electrical connection -Zone 1-

To be sourced locally:

- connection wire: 5 x 20 AWG shielded cable

Wiring

Fig. 7.4

The spark detectors (A) must be wired in parallel in the supplied

junction box (B). Each set consists of one spark detector with

EOL resistor (“EOL”) and one without (“no EOL”), which is

marked on the spark detector housing.

Fig. 7.4

7

SPARK DETECTOR SET

Scope of supply:

- spark detector*) +

fixation screw

- spark detector REOL*)

**) + fixation screw

- junction box

- installation set (hole saw

Ø 38 mm + insertion

tool)

*) with alarm resistor (RAL)

**) with end of line resistor

(REOL)

WARNING

To avoid dirtying the lens, never mount the spark

detectors on the bottom of the duct.

Installation is easier if the inside of the duct is

accessible.

WARNING

To prevent false alarms, ensure that no light can get

between the flange and the duct. Seal any holes with

metal foil. Do

not

use duct tape since this may let

through infrared light.

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...