0507347110/160114/B SHIELD fire safety solutions (5k1)

| GENERAL | EN - 3

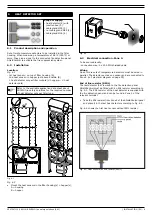

suppression system. In case of alarm, a

fire alarm sounder

(K) will go off. Operational reliability in the event of a power

failure is assured by a battery pack. To secure the overall

functionality, ShieldControl monitors open or short circuit of

wiring loops of detectors and the suppression system.

When a fire is detected, the system can be activated manually

at the

manual call point

(L).

Automatic detection is triggered by heat, sparks or smoke. The

filter is fitted with

heat detectors

(H) above the dustbin and at

the top of the filter.

Spark detectors

(C) are placed near the

filter outlet and in the duct after the filter. A

smoke detector

(D), suitable for air ducts, is placed in the duct after the filter.

The inlet and outlet duct of the filter are fitted with pneumatic

sliding valves

(B). If there is a fire, the valves close and cut off

the oxygen, thereby choking it. This constrains the risk of

escalation. When the extraction system is switched off, the

valves are closed as well to create a safe situation. The valves

have reed contacts to monitor the closing function; the filter

system software runs a periodic check.

The filter is fitted with one or more

FlameShield

(I) aerosol fire

extinguishing generators. The generators are placed directly in

the filter housing and do not require plumbing. FlameShield

requires no maintenance and has a service life of 10 years. If

there is a fire, FlameShield is activated by the fire detection

panel after the sliding valves have closed. FlameShield self

activates at 300°C (572°F). Fire suppression is rapidly achieved

through interference between the aerosol and the flames’ free

radicals, terminating propagation of the fire. The aerosol

remains active during 30 minutes after activation, thus

preventing re-ignition. The amount of aerosol is proportional to

the filter volume and can be easily adapted by adding

generators.

The

system control panel SCP

(M) controls the filter and fan

operation. If there is a fire, it will get a signal from the fire

detection panel and close the sliding valves, stop the fan and

shut off the supply of compressed air. The filter compressed air

connection is fitted with a

solenoid valve

(G) that will allow the

compressed air tanks to depressurize outside of the filter and

prevent any fresh oxygen from reaching the fire.

Fig. 1.1

1.4

System maintenance

The entire system including the ShieldControl panel must be

tested periodically in accordance with the national fire

protection association requirements or the authorities having

local jurisdiction.

The maintenance and testing procedure of the separate

components is described in the relevant chapter.

General instructions

If maintenance is required to any detector, the filter system or

peripheral equipment, proceed as follows.

•

Isolate the FlameShield module(s).

After maintenance:

•

Follow commissioning instructions.

•

Make sure switch of ShieldControl panel is in

RUN

mode.

Refer to the available application data sheet about

SHIELD fire safety solutions for more detailed

information.

A

E

F

D

H

C

B

J

G

L

K

I

M

ATTENTION!

Prior to performing any test:

- notify the local fire brigade that you will be testing

the fire safety system, especially when the

installation is connected to the brigade control room

- inform all other parties involved, e.g. staff, fire

safety coordinator, alarm monitoring department/

company

Testing the system may lead to acoustic fire alarm

without activating the fire suppression method.

WARNING!

Not isolating the FlameShield module(s) will cause

accidental activation of the fire suppression method.

WARNING!

Not having the ShieldControl panel in

RUN

mode will

disable automatic fire detection and extinguishing

when the system is in operation.

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...