0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 16

9.1

Product description and operation

Double activated pneumatic sliding valve with 5/2 solenoid, to

be installed by two pieces (before and after filter system).

When the filter system is in operation the valves are open. In

case of an alarm or power failure or when the fan is switched off

the valves are closed. Correct closing of the valves is monitored

by the reed contact.

In case of fire, the sliding valves close automatically, operated

by pneumatic cylinders. In sequence to a lack of oxygen the fire

is supposed to choke. This will also minimize risk of escalation

or spreading of smoke.

9.2

Installation

Location:

- 1st sliding valve: in filter inlet duct

- 2nd sliding valve: before or after spark and smoke sensors in

filter outlet duct

- to be mounted in vertical position

It is strongly recommended that the sliding valves be installed

indoors. If they are installed outside, however, ensure that they

are protected from rain and snow. Avoid installation where

compressed air can cool down below its dew point to prevent

damage to the pneumatics.

The sliding valves can be mounted:

- during installation of a new ductwork

- in an existing duct

To mount the sliding valves, proceed as follows.

In case of installation in an existing duct: cut away a piece

of the existing duct as indicated in the table below.

•

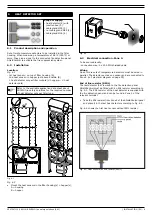

Slide a connection flange (B) into both duct ends (A).

•

Place the sliding valve (D) in between and fasten it using the

quick release clamps (C).

•

Fasten the connection flanges using self-tapping screws.

Fig. 9.1

9.3

Electrical connection

To be sourced locally:

- connection wire: 5 x 20 AWG cable

Wiring

•

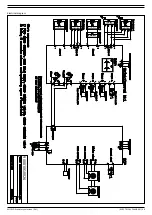

Connect the sliding valves to the system control panel SCP

in accordance with the electrical diagram on page 29.

•

Connect the reed contacts to the system control panel SCP

in accordance with the electrical diagram on page 29.

9.4

Compressed air connection

•

Connect the sliding valves to a compressed air source.

9

SLIDING VALVES

Scope of supply:

- sliding valve incl. 5/2

solenoid valve, reed

contact, junction box and

cable gland (3)

- connection flange (2)

- quick release clamp (2)

WARNING

Do

not

mount the sliding valves in horizontal position

to avoid malfunction of the valves.

ATTENTION

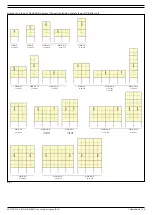

Allow sufficient space above the duct for the sliding

valves to fully open;

- SV-10: + 14 in.

- SV-12: + 16 in.

- SV-16: + 20 in.

- SV-20: + 26 in.

- SV-24: + 32 in.

WARNING

Ensure that the ductwork can carry the weight of the

sliding valves. It is recommended to use duct

supports, especially for sliding valves type SV-16/20/

24.

ATTENTION

The sliding valves are equipped with eye bolts for

lifting purposes during installation. The eye bolts

cannot

be used to mount the sliding valves

permanently.

Type of sliding valve

Duct length to be removed

SV-10

11.6 in. +/- 0.4 in.

SV-12

11.6 in. +/- 0.4 in.

SV-16

11.6 in. +/- 0.4 in.

SV-20

15.0 in. +/- 0.4 in.

SV-24

15.0 in. +/- 0.4 in.

WARNING

The valves must be mounted straight and without

tension on the shell/housing to guarantee airtightness

and to avoid noise by airflow.

WARNING

If applicable, take precautions to ensure that people

are not able to get into the blade's arc of movement.

WARNING

Keep wiring away from places that can become hot

due to fire. Do not use filter or duct as support for

electrical wires.

Compressed air specifications

Compressed air connection

6 mm

Recommended operational pressure

5 bar (max. 9 bar)

Quality

dry and oil-free according to

ISO 8573-3 class 6

B

A

B

A

C

D

C

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...