0507347110/160114/B SHIELD fire safety solutions (5k1)

| INSTALLATION | EN - 7

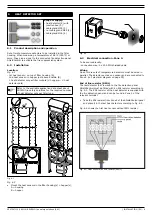

5.4

Electrical connection

Fig. 5.3

ShieldControl (D) must be wired to:

- heat detector set(s) (J)

- spark detector set (H)

- smoke detector (I)

- fire alarm sounder (included in ShieldControl package) (C)

- manual call point (included in ShieldControl package) (B)

- system control panel SCP (E)

ShieldControl activates:

- FlameShield fire extinguishing generator(s) (A)

- fire alarm sounder (C)

- system control panel SCP (E)

System control panel SCP (E) activates:

- sliding valves (G)

- solenoid valve (F)

Fig. 5.3

All connections for field wiring are to the terminal strips along

the top and bottom of the PC board.

Cables to be used:

- 5 x 20 AWG shielded cable for detectors and manual call point

- 5 x 20 AWG normal cable for other wiring

The resistance of any core of any cable should not exceed 25

ohm(>1640 ft for 20 AWG).

To connect the cables to the ShieldControl panel, use suitable

metal cable glands fitted to the knock-outs provided.

•

Connect all cables to the ShieldControl panel in accordance

with the electrical diagram on page 29.

The wiring of the detectors, manual call point, FlameShield and

fire alarm sounder is monitored for open circuit fault conditions.

5.4.1

Battery packs

The ShieldControl panel is fitted with battery leads wired to the

PC board to connect the two battery packs.

•

Place both battery packs inside the ShieldControl panel.

•

Connect them to the battery leads.

5.4.2

Mains supply

The mains supply of 115V/230V AC must be connected to a

clean group or to a group that is not connected to equipment

likely to cause frequent power failures.

•

Connect the ShieldControl panel to the mains in accordance

with the electrical diagram on page 29.

5.5

Maintenance

The ShieldControl panel itself does not require specific

maintenance except for cleaning. Do not use solvents or

detergents and ensure that water cannot enter the enclosure.

Settings

ShieldControl is programmed for automatic activation of the

FlameShield generators five seconds after one of the detectors

or manual call point has been activated. The activation duration

time is 60 seconds.

5.6

Manual call point

5.6.1

Product description and operation

Manual pull station to activate the fire alarm and fire

suppression system.

Operated by pushing in the bar marked “PUSH” and pulling the

handle marked “PULL” on the front of the unit as far down as it

will go. At that point, the handle will lock in place and will be

easily visible up to 50 feet away.

5.6.2

Installation

Location

- where it will be easy for the operator to reach it

- indoors

5.6.3

Electrical connection

To be sourced locally:

- connection wire: 5 x 20 AWG shielded cable

Connect the manual call point to Zone 4 of the ShieldControl

panel in accordance with the electrical diagram on page 29.

•

Take the EOL resistor 5k ohm mounted in the terminal strip

of Zone 4 and place it in the terminal strip of the manual call

point (A).

WARNING

It is extremely important for the polarity of the

batteries to be connected correctly. Incorrect

connections could damage the ShieldControl panel.

E

F

A

B

C

D

F

J

I

H

Component

Action

Frequency:

when-

ever

dirty

every

year

every 4

years

ShieldControl

panel

Clean the outside

using a barely damp

cloth.

X

Battery packs

Test batteries;

POWER

FAULT

LED must be off.

X

Replace batteries.

X

Scope of supply:

- manual call point

- key

ATTENTION

Do

not

install the manual call point to the connected

filter system. It might not be accessible if there is a

fire.

Содержание Shield 5k1

Страница 1: ...www plymovent com EN Fire safety solutions EN Installation and user manual shield 5k1...

Страница 30: ...SHIELD fire safety solutions 5k1 ELECTRICAL DIAGRAM 29 Electrical diagram 900010G0026 0 22 05 2014...

Страница 31: ......

Страница 32: ...www plymovent com 0507347110 160114 B SHIELD 5k1 EN...