5.2.3

General parameters

5.2.3.1

PNU 1000: instrument ID

The instrument ID consists of four ASCII characters, with the contents “S6xx”, whereby xx stands

for the current level of the output stage (e.g. S606).

5.2.3.2

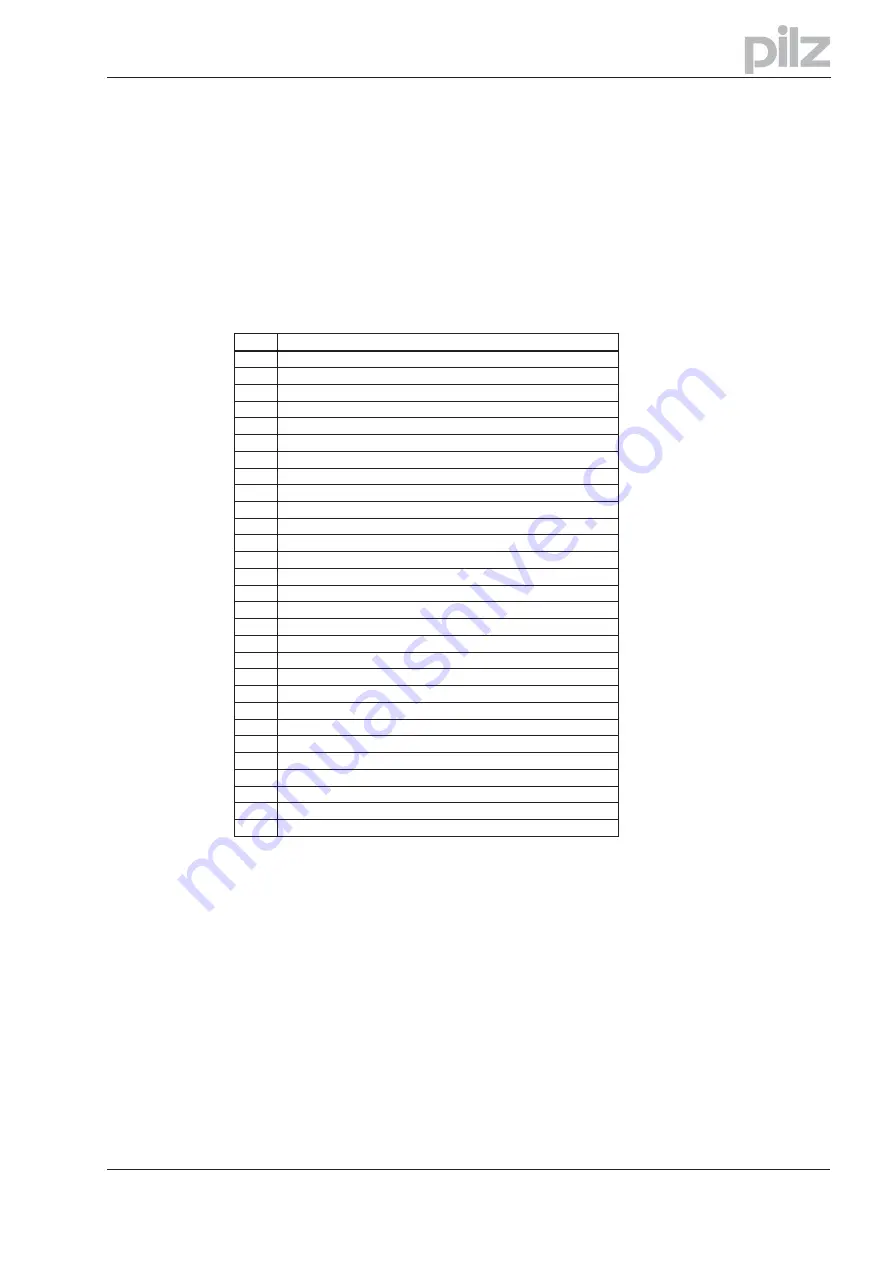

PNU 1001: manufacturer-specific error register

The assignment of the error register can be seen in the following table. The explanation of the indi-

vidual errors can be found in the assembly & installation instructions for the servo amplifier.

Bit

Description

0

Error F01:

Heatsink temperature

1

Error F02:

Overvoltage

2

Error F03:

Contouring error only with SERCOS

3

Error F04*:

Feedback

4

Error F05:

Undervoltage

5

Error F06*:

Motor temperature

6

Error F07*:

Auxiliary voltage

7

Error F08:

Overspeed

8

Error F09*:

EEPROM

9

Error F10*:

Flash-EEPROM

10

Error F11*:

Brake

11

Error F12*:

Motor phase

12

Error F13:

Internal temperature

13

Error F14*:

Output stage

14

Error F15:

I²t max.

15

Error F16:

Mains supply-BTB

16

Error F17*:

A/D-converter

17

Error F18*:

Ballast

18

Error F19:

Mains supply phase

19

Error F20*:

Slot error

20

Error F21*:

Handling error, plug-in card

21

Error F22:

Erdschluss

22

Error F23:

CAN-Bus off

23

Error F24:

Warning

24

Error F25:

Commuation error

25

Error F26:

Limit switch

26

Error F27:

AS-Option

27-30 Error F28 - F31*:

reserved

31

Error F32*:

System error

When the cause of the error has been cleared, the error state can be canceled by setting Bit 7 in

the control word.

The error response of the PMCtendo DD4 to the reset will differ, depending on the error that has

occurred:

For errors that are marked by an asterisk, setting the reset bit initiates a cold-start of the drive,

whereby the PROFIBUS communication to this instrument will also be interrupted for several sec-

onds. Depending on the circumstances, this break in communication may have to be separately

handled by the PLC.

For the other errors, the reset leads to a warm start, during which the communication will not be

interrupted.

A description of the individual errors and recommendations for removing them can be found in the

installation manual.

User manual PROFIBUS DP PMCtendo DD4

Page 25

5 Using the parameter channel

Содержание Motion Control PMC

Страница 1: ...Motion Control PMC User manual Item No 21 522 02 Communication profile PROFIBUS DP for PMCtendo DD4 ...

Страница 8: ...This page is deliberately left blank Page 8 User manual PROFIBUS DP PMCtendo DD4 ...

Страница 10: ...This page is deliberately left blank Page 10 User manual PROFIBUS DP PMCtendo DD4 2 Important ...

Страница 14: ...This page is deliberately left blank Page 14 User manual PROFIBUS DP PMCtendo DD4 3 Installation Setup ...

Страница 44: ...This page is deliberately left blank Page 44 User manual PROFIBUS DP PMCtendo DD4 6 Process data channel ...

Страница 62: ...21 522 02 2005 10 Printed in Germany ...