Assembly and Operation Manual

26

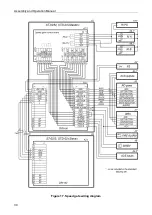

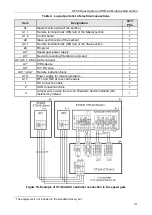

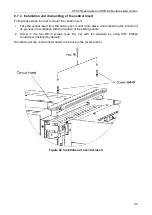

As a matter of convenience, inputs and outputs of the built-in ACS controller may be

connected not to the DIN rail contacts, as shown in the layout (Fig. 17), but directly to the

corresponding contacts of the control board (

X2

and

X3

connectors, Fig. 6). Connection

layout variant is shown in Fig. 18 .

Note:

It is recommended to install the ACS controller

Ethernet

connector so it is faced in the

direction of the sliding panel motor drive, to ensure more convenient access to it in the

future.

Use double-sided tape to secure the readers. Carefully route the cables from the readers to

the ACS controller (to the cable entry point from the ACS controller), by using the standard

gaps in parts of the section housing. Use self-adhesive pads and cable ties to secure the

cables.

Attention!

Do not route the connecting cables and wiring through the speed gate operating

mechanism inside the housing of the section in order to avoid its failure!

19. Check that all electrical connections are correct and safe.

20. Check that the jumpers and switches on the speed gate control board are set correctly (see

section 5.2.4). Set the speed gate operating mode (

pulse

or

potential

) by using the

Pulse

switch located on the control board, and set the speed gate operating mode (

normally open

or

normally closed

) by using

XP2 (Mode1)

jumper.

21. Unpack the sliding panels (1), filling glass (2), section glass covers (3), central inserts (4) and

side panels (6) (boxes No.2, No.4).

22. Assemble the parts of all sections in the following order (see sect. 8.7):

•

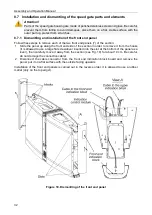

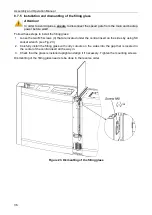

Install the front end panels (7) (see sect.8.7.1 , Fig. 19). The panel with the front end

indication block (8) must be mounted on the side of the section with the indication control

module, and the corresponding connection cable must connect the indication control

module and the front end indication block (see Fig. 19). The connection cable connected

to the

ARROW

connector of the indication control module will activate the white arrow

on the front end indication block. The cable connected to the

CROSS

connector will

activate the red cross.

•

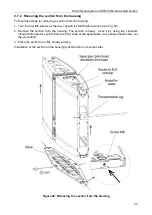

Mount the central insert (4) (see sect.8.7.4, Fig. 22 ).

•

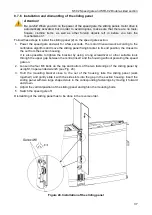

Mount the filling glass (2) (see sec.8.7.5, Fig. 23).

•

Mount the sliding panels (1) (see sec.8.7.6, Fig. 24).

Note:

If needed, reduce the distance of the sliding panel departure from the housing of the

STD-02.900

double-sided section (for arrangement of the passageway with a width of 600

mm on one side), it is necessary to mount the sliding panel departure limiter and install a

jumper on the sliding panels motor drive board (see section.8.7.9).

•

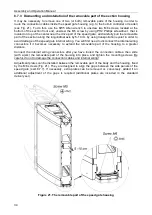

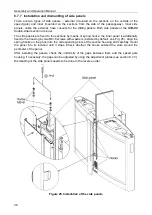

Install the side panels (6) (see sect. 8.7.7, Fig. 25).

•

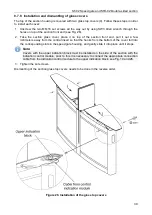

Mount the glass top covers (3) (see sect. 8.7.8, Fig. 26), the cover with the upper

indication block (5) must be mounted on the side of the section with the indication control

module, prior to that it is necessary to connect the appropriate connection cable from the

indication control module to the upper indication block (see Fig. 19).

23. Test each passageway of the speed gate according to sec.9.1.

24. Check the operation of all passage lanes of the speed gate by sending control commands

from the RC-panel (see section.9.2, 9.3).

The speed gate is ready for operation after finishing installation and test procedures.

Содержание ST-02 Series

Страница 1: ...CERTIFICATE ST 02 Speed Gate STD 02 and Double Sided Section ...

Страница 2: ...ST 02 Speed gate and STD 02 Double sided section Assembly and Operation Manual ...

Страница 31: ...Assembly and Operation Manual 30 Figure 17 Speed gate wiring diagram ...

Страница 49: ...www perco com ...