Conversion

Before wheel balance testing, the operator can

sometimes forget the input data from the rim. Data

can be entered after testing wheel balance. Then it

is not necessary to do a balancing test again.

The operator only needs to press the [SET] key, the

system can recalculate the imbalance value with

new data. Below the interface that shows the

imbalance value, press the [SET] button to check

the currently entered data on the rim.

Unbalance optimize

If the wheel imbalance value is over 30 grams, the

system will appear ”OPT”, indicating to perform

imbalance optimization. Imbalance optimization

has two working methods:

If the balance value is already displayed- If you

have already completed the balancing test, press

OPT when you need to optimize the process

balance.

Use chalk mark as a reference point on the flange

and rim and the tire, use the tire changer to change

the rim and tire by 180 °. Put the wheel back on the

balancer and check that the marking of the

reference point between the flange and the rim

must be in the same position. Quickly rotate the

wheel to the balance wheel after rotation stop.

As the figure above, the left display shows the

percentage of optimize. If before optimization of

static value is 40 grams, optimized percentage is

85%, so after optimizing static value only 6 grams

remain (15% × 40 grams = 6 grams). Slowly rotate

the wheel by hand, when both end sides two of the

position indicator light flash, see picture below, use

chalk to mark on the tire.

Slowly rotate the wheel by hand again when the

indicator lights for both flash, use chalk to make a

mark on the rim.

Remove wheels from the balancer, use tire

changers to remove tires from rims. Attach the tire

to the rim to place the tires and rim marks in the

same position. Optimize completely. After

shutdown and before balancing, imbalance can

also be optimized immediately. Turn on the power,

mount the wheel, press the OPT key, left side

shows OPT, quickly rotate the wheel for balancing

testing. When the rotation ends shows the display

operation. Press the [SET] button to stop operation.

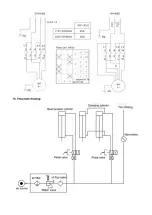

Self-calibration of dynamic balancing

The self-calibration of dynamic balancing was

completed before ex-factory, but the system

parameter may vary due to long-distance transport

or long-term use, which may cause errors.

Therefore, users can do self-calibration after a

while. After starting the machine, the initialization

is complete, fit a medium-sized balanced rim that

can be clamped with a counterweight, follow the

instructions for entering data on the rim. Press the

[FINE] + [SET] key, turn the wheel manually, when

the display is off, move the handle to rotate the

wheel. When the display shows ”REDUCE”, it means

that the rotational speed is faster now. When the

rotation speed reaches normal speed, the display

shows ”RUN ---”. When the display shows ”STOP”,

the wheel stops rotating. Press the [SET] button to

exit.

According to the picture below, you squeeze a 100

gram counterweight anywhere outside the rim

manually rotate the wheel, when the display is off,

move your hands away to go to the next step, press

the [SET] button to exit.

According to the picture below, the wheel stops

rotating and the calibration is completed. Remove

the tire.

Gram-Oz conversion operation

How to Convert the Counterweight Concentration

(Gram-Oz)

Press the [a-] or [a +] button.

Содержание 498192

Страница 1: ...Tyre changer balancer 2 in 1 D ckmaskin balanserare 2 i 1 Item No 498192...

Страница 11: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 33: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......

Страница 46: ...Verktygsboden Erfilux AB K llb cksrydsgatan 1 SE 507 42 Bor s Verktygsboden Bor s Sweden 0120504 03...