6

-9-3.

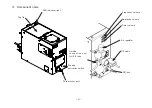

Holding plate adjustment

$$

%%

$

$

%

%

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

㺦㺚㺼ᢲ࠼ᯈ

㺸㺎㺷

㺛㺵㺐㺢㺼㺪㺼㺹㺍㺖

㐺⏝㺦㺚㺼

⣙

㹼

PP

㺦㺚㺼ᢲᯈ

㺦㺚㺼ᢲᯈ

Space between holding plate and screw shall be roughly 0.5

~

1mm.

・

If there is no clearance, a screw will be blocked. If the clearance is too

large, screw piling or screw jump out will occur.

When the holding plate adjusting screw is turned clockwise, the plate moves down.

When the adjusting screw is turned counterclockwise, the plate moves up.

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

Holding plate

Holding plate fixing screw

Adjus. screw

6

-9-4.

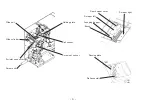

Slide unit adjustment

Remove both side covers, front cover, rail screw sensor mounting bracket and holding plate, and check the positions of the

rail and slide block grooves from above the machine.

-Check the center position of the groove of the rail and slide block

⇒

Visually make it almost in the center.

-Check the height of the rail and slide block

⇒

Lower the upper surface of the rail and the screw receiving part of the slide

block by about 0.2 mm on the slide block side.

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

Rail screw sensor

mounting bracket

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

$$

%%

$

$

%

%

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

㺦㺚㺼ᢲ࠼ᯈ

㺸㺎㺷

㺛㺵㺐㺢㺼㺪㺼㺹㺍㺖

㺦㺚㺼ᢲᯈ

㺦㺚㺼ᢲᯈ

- 17-

Rail assembly

Holding plate

Loaded screw

Slide block

0.5 ~1㎜

Holding plate

Rail assembly

Slide block

Slide block

Rail assembly

Holding plate