47

14 - Wheel System, Non-Traction

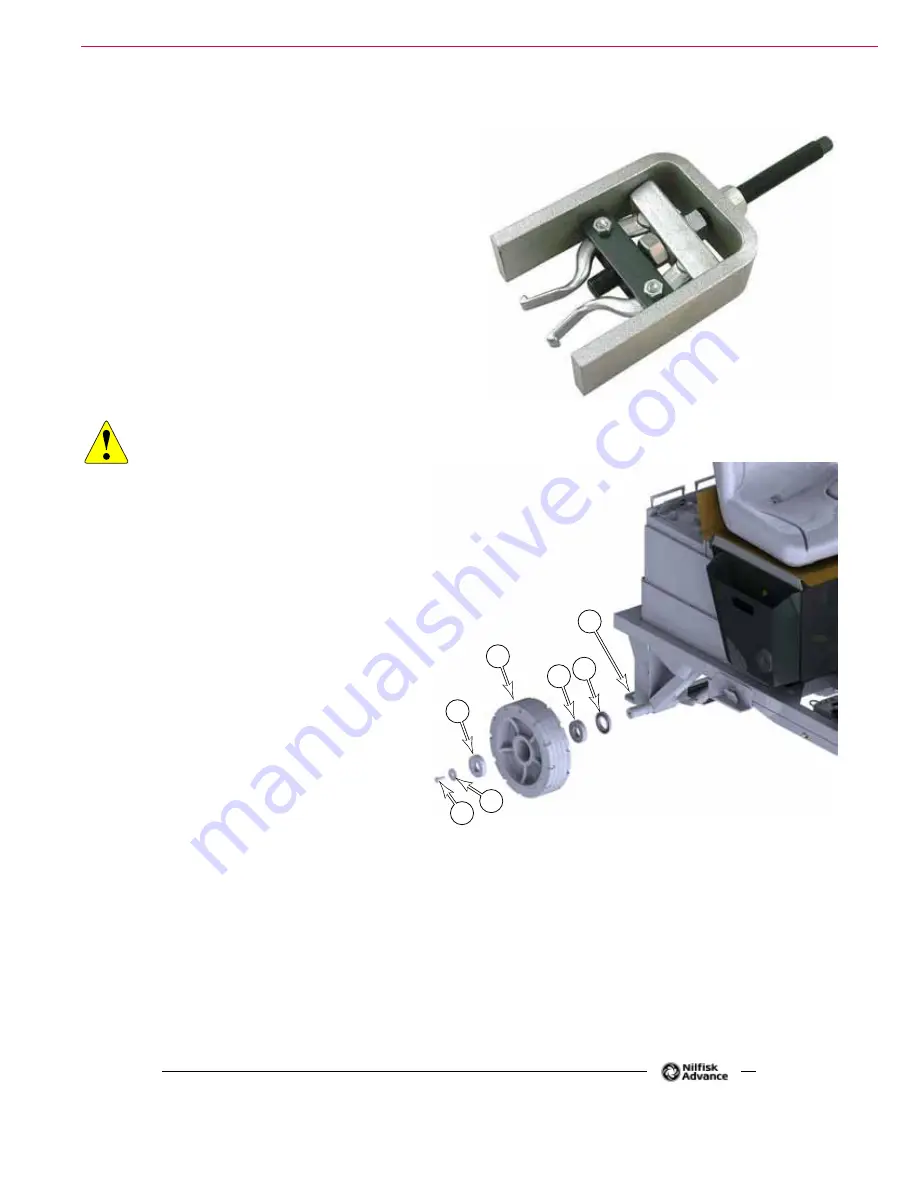

Removal and Installation

Rear Wheel Bearings and Seal

The rear wheel bearings are sealed and do not require

lubrication Severely worn bearings may be detected

by wheel wobble or grinding sounds A less obvious

symptom of bearing failure is when the wheel easily

freewheels when spun by hand with the machine

elevated off the ground A good sealed bearing should

have a slight but smooth resistance to freewheel

The wheel bearings are pressed into the wheel hub To

complete this procedure, you will need a bearing puller

and a press There are many different types of bearing

pullers that will operate on the internal bore of a bearing

(35mm in this case) As one example, a pilot bearing

puller is shown to the right

WARNING: Never work under a machine without safety

stands or blocking to support the machine.

1 To reduce the weight of the machine, drain

both the recovery and solution tanks

2 Carefully pry off the wheel hub cover (not

shown)

3 Jack the rear of the machine and block both

sides of the machine at the rear lifting points

(A)

near the wheels to keep the machine

stable and prevent it from rolling

4 Remove the bolt

(B)

and washer

(C)

that

secure the wheel to the axle, and remove the

wheel

5 Using a seal puller or similar means, pull the

inboard seal

(F)

from the wheel hub

•

The act of removing the seal will destroy

the seal You must replace the seal with a

new one

6 Using a suitable bearing puller, remove both the inboard and outboard bearings

(E)

7 Press new bearings into the hub Make sure to press along the outer race (72mm Ø) to avoid damaging

the bearing

8

Press a new inboard seal into the hub, and apply a light film of grease to the seal lip.

9 Reinstall the wheel

F

E

E

D

C

B

A