126

40 - Recovery System

Functional Description

The recovery system extracts wastewater from the

floor collected by the squeegee, and deposits it into

the on-board recovery tank

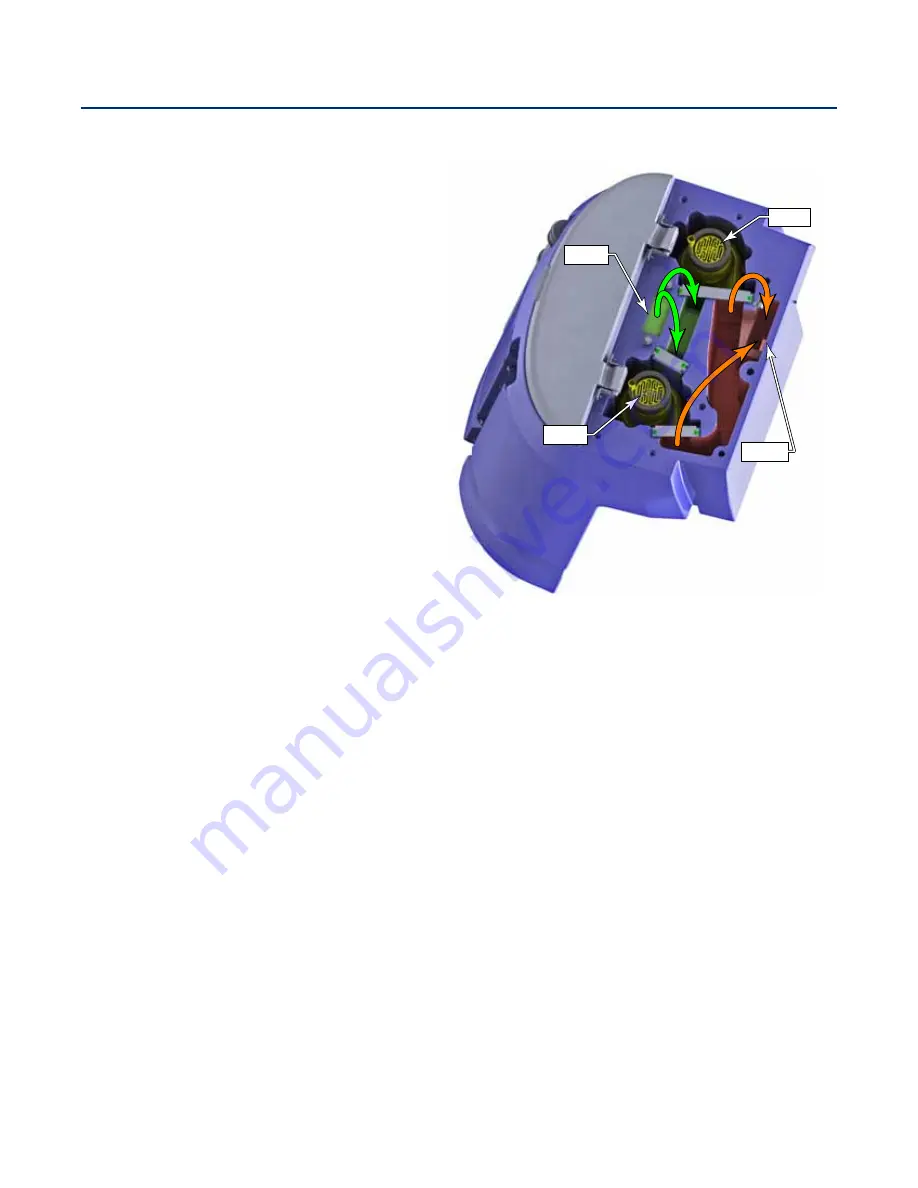

Vacuum Motor and Recovery Tank

The SC6000 machine has one standard vacuum

motor, plus an optional second vacuum motor for

higher vacuum draw The vacuum motor generates

airflow through the recovery tank and suction

hose to the squeegee The high velocity air at the

squeegee pulls the wastewater off the floor and up

through the suction hose As the mixture of air and

water enters the recovery tank, the airflow slows

down due to the larger space, and the water drops

out of the airflow and into the tank.

The airflow passes through an inlet screen to

prevent debris from entering the impeller of the

vacuum motor The exhaust air is expelled through

ducting in the machine toward the floor so it can be

dispersed without blowing directly on the operator

or the work environment

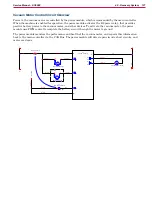

Operational Mode Prerequisites

Before the main controller can activate any of the operational modes, it must first check that the appropriate

prerequisites are met

•

Recovery System Outputs

– Vac motors M4 and M5 – Recovery mode (Seat switch closed upon entry) or Squeegee Actuator M6

◦

No recovery system fault (vac motors and squeegee)

◦

Throttle command not equal to zero (and not timed out)

◦

No Estop inhibit

◦

No impact lockout inhibit

◦

No low voltage cut out inhibit (second stage)

◦

No RTF inhibit

◦ Note M5 also requires Vacuum option set to dual in configuration menu

– Vac motors M4 and M5 – Wand mode (seat switch open upon entry) or Squeegee Actuator M6

◦

No recovery system fault (vac motors and squeegee)

◦

No Estop inhibit

◦

No impact lockout inhibit

◦

No low voltage cut out inhibit (second stage)

◦

No RTF inhibit

◦ Note M5 also requires Vacuum option set to dual in the configuration menu

Vac 1

Vac 2

Inlet

Outlet