107

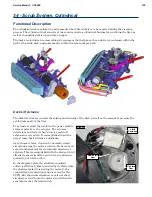

34 - Scrub System, Cylindrical

Adjusting Travel

If the leadscrew travel needs to be adjusted, complete

the steps below Otherwise, skip down to Setting the

Leadnut Position

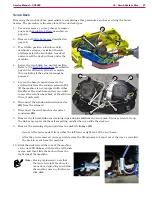

7 Remove the dust cap from the top of the actuator

covering the adjustment cam

8

Using a 1/2” socket, turn the adjustment cam:

•

Turn the cam only a couple of clicks at a time

before rechecking the result

•

Each click of the cam represents about 2mm

of leadnut travel

•

Turn the cam clockwise to raise the leadnut

and increase the travel distance

•

Turn the cam counterclockwise to lower the

leadnut and decrease the travel distance

•

The target travel is: 2 .22 ± 0 .09”

(56 ± 2 mm)

9 After adjusting the cam, cycle the actuator and recheck the travel distance

Setting Leadnut Position

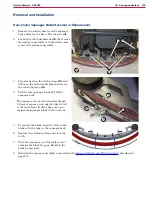

After the leadscrew travel has been set, it is

necessary to adjust the final position of the

leadnut You will notice that the leadnut position

is less than the leadscrew travel In the retracted

position, the leadnut should be bottomed out and

the spring slightly compressed

10 Extend the actuator until it stops

11 Manually turn the leadnut until the leadnut

distance is 1 67 to 1 90 inch (42 5 to 48 2

mm)

12

While holding the leadnut from turning, cycle the actuator to confirm its motion.

13 After the adjustment is complete, make sure the leadnut does not turn while you are reinstalling the

actuator

Troubleshooting Notes:

•

If the actuator will neither raise nor lower, then both cams are activating their limit switches at the same

time

– Rotate the cam clockwise several clicks

–

Do not hold the nut

, and raise and lower the actuator until it cycles normally again

– Go back and restart the adjustment with the extended limit adjustment

• If you are using the “Output Test” method, and the main machine controller sees the actuator go active

again after being stopped on a limit position, the controller will issue an error, and need to be reset This

may occur when you are turning the cam clockwise

Cam Lobe

1/2" Hex

Adjustment

E

G

F

1.67-1.90” (42.5-48.2 mm) Extended