12

© by N&W GLOBAL VENDING SpA

02-2007 266 00

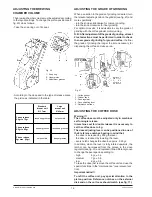

INSERTING THE SELECTION LABELS

The selection labels are supplied with the machine and

must be inserted at the time of installation according to the

layout and to the language (see “selection dose” table).

According to the layout settings, the buttons may perform

different selections.

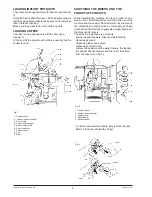

CONNECTING THE MACHINE

TO THE WATER MAINS

The machine must be connected to the drinking water

mains, taking into account law provisions in force in the

country where the machine is installed.

The water pressure must be 7.3 to 123.3 Psig (0.5 - 8.5

bar).

Run some water from the mains until it is clear and without

impurities.

Use a hose capable of withstanding the water mains

pressure and suitable for use with foodstuffs (minimum

inside diameter of 6mm) to connect the water supply to the

3/4" gas-type union of the water inlet solenoid valve.

OVERFLOW DEVICE

The water inlet solenoid valve (see fig. 15) is equipped with

an overflow device which mechanically stops the water

inlet if there is a malfunction in the solenoid valve or in the

boiler water level control device.

To restore normal operation, proceed as follows:

- disconnect the electricity from the machine;

- drain the water contained in the overflow hose;

- shut off the water supply using the tap outside the

machine;

- loosen the nut which secures the solenoid valve

supply hose to relieve the water mains residual pres-

sure and then tighten again (see fig. 15);

- open the tap and switch the machine on.

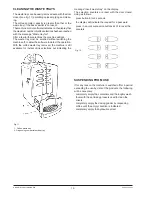

WATER SOFTENER UNIT

The machine is sold without water softener.

Should the water be very hard, a water softener unit can be

installed.

The water softener, available as accessory, must be

replaced or regenerated regularly following the directions

from the manufacturer.

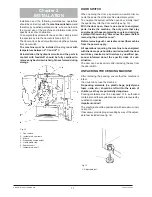

CONNECTING TO THE POWER SUPPLY

The machine is designed to operate under single-phase

120V~ voltage and is protected by 15 A fuses.

Before making the connection, ensure that the rating

corresponds to that of the power grid, and more specifi-

cally:

- the supply voltage rating must be within the range

recommended for the connection points;

- the main switch should be capable of withstanding the

peak load required, and at the same time ensure

proper omnipolar disconnection from the power grid

with an opening gap of the contacts of at least 3 mm.

The switch, the power outlet and the plug must be

located in an easily accessible position.

The electrical safety of the machine is ensured only when

it is correctly earthed according to the safety standards in

force.

This fundamental safety requirement must be duly

verified, and if in doubt the system must be carefully

tested by qualified technicians.

The power supply cable is of the type with a fixed plug.

When necessary, the power supply cable (see fig. 16)

should be replaced by qualified personnel only, using

cables type UL SJTO 3x16 AWG.

Do not use adapters, multiple sockets and/or exten-

sions.

THE MANUFACTURER DECLINES ALL RESPONSI-

BILITY FOR ANY DAMAGE CAUSED BY NON-COM-

PLIANCE WITH THE ABOVE MENTIONED PRECAU-

TIONS.

Fig. 15

1 - 3/4" water inlet hose

2 - Water supply hose

3 - Overflow hose

Fig. 16

1 - Lift cover

2 - Cable clamp

3 - Power supply cable

Содержание Colibri UL 120V

Страница 2: ......

Страница 4: ......

Страница 44: ...N W GLOBAL VENDING S P A Sx39701...

Страница 45: ...Colibr UL 120V Schema elettrico funzionale espresso semiautomatico...

Страница 46: ...N W GLOBAL VENDING S P A Sx44700...

Страница 47: ...Colibr UL 120V Schema elettrico funzionale espresso automatico...

Страница 48: ...by N W GLOBAL VENDING SpA NOTE...

Страница 49: ...by N W GLOBAL VENDING SpA NOTE...

Страница 50: ...by N W GLOBAL VENDING SpA NOTE...

Страница 52: ......