2-19

2

2

2

2

Test Printing

Print a test pattern to check that there are no discharging

defects such as nozzle missing (slight touching of ink or

nozzle missing).

In addition, you can select the orientation of the test

pattern to print from two types in order to perform test

printing repeatedly. Select one depending on your use.

1

Press the

(TEST PRINT/CLEANING)

,

and press the

key in LOCAL.

• TEST PRINT MENU appears.

• Press [

][

] to change the test pattern

orientation.The orientation selected here will be

reflected on when you will print next time.

• When performing test printing after having

changed the orientation from "SCAN DIR." to

"FEED DIR.", the line is fed to the position of the

first test printing.

2

Press the

key.

• Test printing starts.

• When the printing has been completed, the

screen returns to LOCAL.

3

Check the printed test pattern.

• When the result is normal, end the operation.

• When the result is abnormal, perform head

cleaning. (

Head Cleaning

About head cleaning

Check the printed test pattern result and perform cleaning

depending on the status.

Select one from the three types below:

Soft

: When lines are bent, when any line is missing

Normal

: When any line is missing, when colors are

mixed

Hard

: When poor image quality cannot be improved

even by Normal or Soft cleaning

Perform head cleaning depending on

the test printing result

There are three types of head cleaning. Use one by

checking the test pattern.

1

Press the

(TEST PRINT/CLEANING)

,

and press the

key in LOCAL.

2

Press

to select “CLEANING”, and

press the

key.

• CLEANING MENU appears.

3

Press

to select the cleaning type.

•

Soft

: When lines are bent, when any line

is missing

•

Normal

: When any line is missing, when

colors are mixed

•

Hard

: When poor image quality cannot be

improved even by Normal or Soft

cleaning

4

Press the

key.

5

Press

to select the cleaning

head, and press the

(

).

• After selecting the head, press the [FUNC2] key

and put a check in the check box.

The head whose box has been checked will be

cleaned.

• To have all head cleaned, put a check in all check

boxes.

6

Press the

key.

7

Perform test printing again, and check the

result.

• Repeat the cleaning and the test printing until the

drawing result becomes in normal.

Check before test printing.

• If a media has been set

• If the origin position has been set

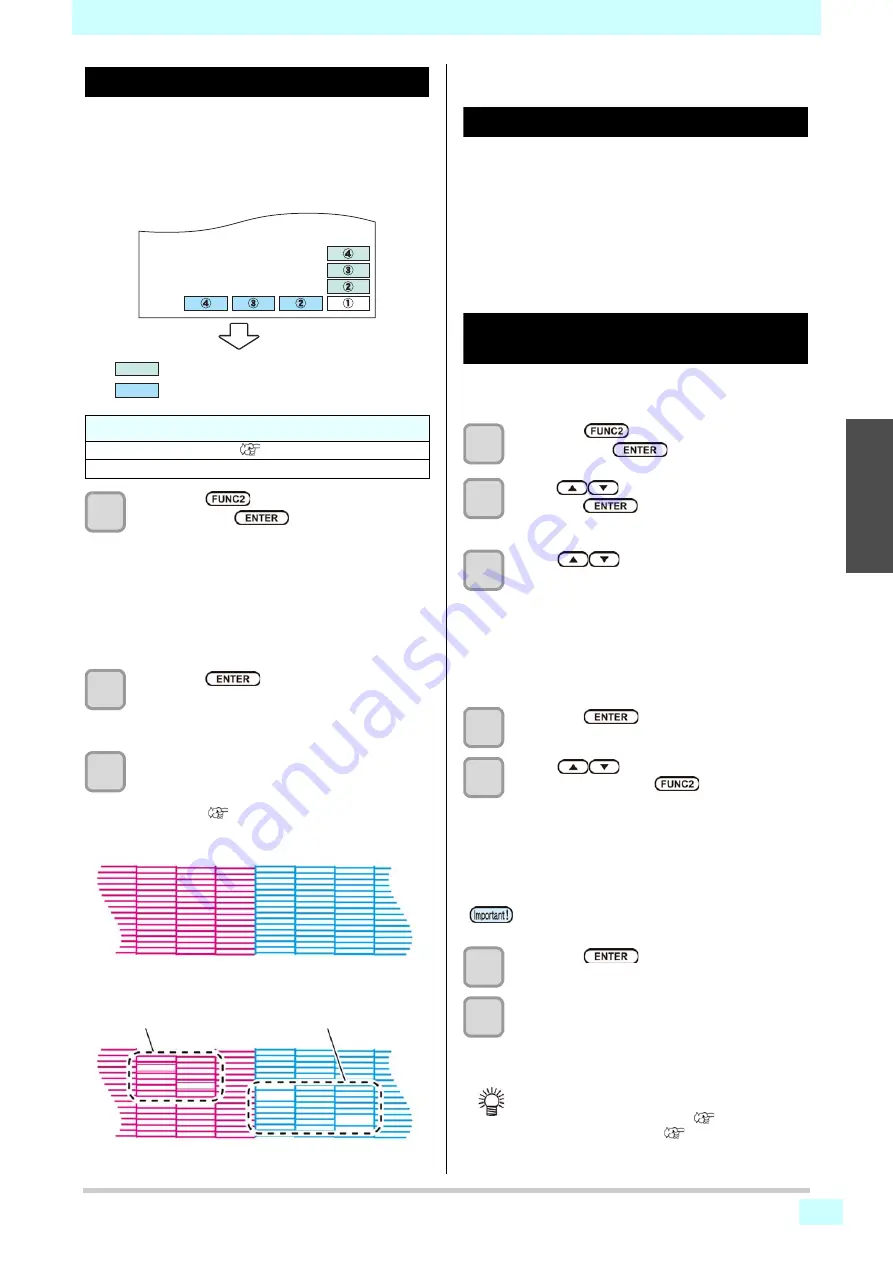

Media-feeding direction

: When the set value is "FEED DIR."

: When the set value is "SCAN DIR."

Abnormal pattern

Clogged with ink

Normal pattern

Nozzles are dirty

In firmware version 1.5 or later, the software

Cleaning is performed for all heads.

When the image quality is not improved after the

head cleaning.

• Clean the wiper and ink cap. (

• Wash the head nozzle. (

Содержание SWJ-320EA

Страница 1: ...MIMAKI ENGINEERING CO LTD https mimaki com D203278 13 Original instructions ...

Страница 72: ...3 24 ...

Страница 116: ...KM FW 1 5 MIMAKI ENGINEERING CO LTD 2018 ...