UK: Martindale Automatic Welding Helmet 9/13 User Instructions

FR: Casque de soudage automatique (Teinte 9/13)

– Mode d’emploi

ES: Instrucciones de casco para soldar automático 9/13

DE: Automatischer Schweißhelm 9/13

– Gebrauchsanleitung

024-001-783 REV A 03/17 Pag

e

2 of 39 M23AWH/13

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

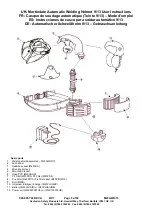

To use :

Plug the charger into the main power supply (100- 240V AC

– 50-60 HZ). When no battery is connected, the LED (Light emitting

Diode) indicators light on the front of the charger should not be lit. When charging the battery connected to a turbo unit the turbo unit

must be turned off.

Plug the charging connector into the socket in the rear of the battery pack. The Red LED indicator will flash for a few seconds indicating

that the charger is checking the status of the battery pack. The Red LED should then light continuously indicating that the battery is being

charged. When the battery is fully charged the red LED will go out and the green LED will indicate. At this point the

battery will be in “Trickle charge” mode, this will maintain the battery’s charge. The battery can be left permanently connected, if desired,

until required for use.

Note :

A new battery, a battery stored for a very long period or a battery that has been run completely flat so that is deeply discharged

may not function correctly.

If when starting to charge such a battery the Red LED continues flashing for more than 10 seconds the charger has detected either a

very deeply discharged battery or a faulty battery. If the Power unit is to be stored without use for more than 3 months the battery must

be detached from the power unit before storage.

Allow the charge to continue as the charger will try and trickle charge the battery up to an acceptable pre-set level before commencing

the battery charge, when the Red LED will continuously illuminate (this may take several hours). If the charger refuses to charge the

battery it may be faulty

– contact Centurion Safety Products for further help and assistance.

It is possible that a battery in this state may require several charge attempts to fully charge the battery. It is not recommended to deeply

discharge a battery by running the power unit until the battery is completely flat since this may permanently damage the battery.

3.2

Respiratory Filters

Pre-Filters Part Nr: (M23PF/10)

The Pre-filter is available as an optional item which sits in front of the main filter and removes coarse dust before it reaches the main

filter.

Pre-filters, in themselves, do not offer any respiratory protection and hence must only be used in conjunction with a main

filter.

Pre-filter should be changed regularly and should be changed if the airflow indicator or electronic low flow alarm indicates low flow

or if the pre-filter appears blocked or clogged. Frequent changing of the pre filter will maximise the life of the main filter.

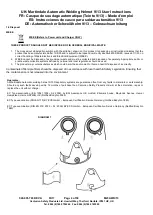

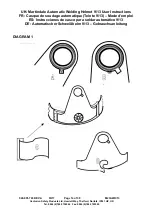

Pre-filter fitting/changing

To fit the pre filter open the unit as detailed below and remove any existing pre filter. Lay the pre filter in the inside of the front door,

ensuring that it is central. Ensure that the vertical ribs in the inside of the door protrude though the slots in the top and bottom edges of

the pre filter). Then close the door as detailed below. Ensure that you do not damage or dislodge the main filter when you are doing this.

Main filters Pt No (M23P2/5) (M23P3/5)

If after changing the pre-filter the flow indicator or electronic low flow alarm still indicates low flow, the main filter should be changed as

detailed below.

If a Pre-filter is not used the main filter should be changed if the indicator shows low flow.

Care should be taken when handling filters.

•

Do not touch the pleated paper filter medium.

•

Do not use filters after their expiry date.

•

Do not use damaged filters.

•

Do not use filters with damaged or missing filter seals.

Filters should be fitted as follows

.

Remove the front cover by easing open the right hand side. (the left hand side is hinged onto the main body)

Fit the filter squarely into the Power unit. Close the cover over the filter by pressing down on the right hand side of the cover until it snaps

home, taking care that the filter cover does not touch the filter media as it is closed.

Filters and Pre-filters must only be fitted to the power unit and not to the head piece.

3. AIR FLOW AND WARNING DEVICES

– See User Instructions Supplied with Magnum PAPR

4. POWER UNIT FITTING

– see User Instructions for Power Unit

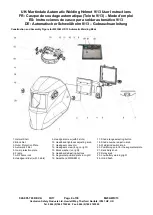

6. WELDING SHIELD FITTING

Whilst supporting the headpiece. Check that air is coming out of the front of the air channel in the welding visor and adjust the crown

strap as required to comfortably position the height of the head harness on the head.

Don the welding visor and tighten the headband using the rear ratchet knob. Locate the Head/ face seal under the chin ensuring a

snug fit around the face ensuring no gaps*.

Locate head/face seal over the crown of the head ensuring no gaps.

NOTE

*The Head/ face seal has an elasticated shock cord drawstring incorporated in it which should be adjusted to suit, using toggle

provided.