4

1

1.1

1.2

Maintenance

We recommend maintenance after 12 months or 500 operating hours to guarantee a long service life

for the motor. The maintenance intervals should be shortened for extreme operating conditions. It is

advisable for maintenance to be carried out by the manufacturer’s service technicians. If you proceed

with maintenance yourself, the planetary gears, needle bearings and motor seals must be lubricated

with a suitable grease (see

lubricants

). Please note that a long service life of the lamella is not guaranteed

when the compressed air is totally dry.

Warning

The motor lamellae contain PTFE. Please comply with the normal health and safety recommen dations

for these materials. Avoid open flames to prevent any ignition/fumes forming from particles detached

from the lamellae. Fumes caused by PTFE particles can cause allergic reactions under certain conditions.

Important

After you have performed any maintenance work on the motor, check that it will work properly. To do so,

drip 2 – 3 drops of oil in the air intake and let the motor run for a few seconds in idle mode.

Guarantee

The manufacturer grants a 12 months guarantee on material and design faults for compressed-air motors

used in single-shift operation. Damage caused by wear, overload or improper handling and by failure to

comply with the instructions is not covered by the guarantee.

Complaints can only be dealt with if the motor is sent

undismantled

to the manufacturer and only if

original parts were used during any maintenance work.

General Information

Compressed air motors by MANNESMANN DEMAG protected against explosions comply with

EEC Directives 2014/34/EU (ATEX) and are assigned to device group II zone 1, 2 and zone 21, 22.

Maximum ambient temperatures

The air motors are classified by temperature classes with a maximum ambient temperature range.

The air motors are only allowed to be operated within the given ambient temperature range.

Valid Zones

Explosion protected air motors which are assigned to group II, category 2G (gas) or category 2GD (dust

and gas) can be operated in zone 1 (gas) or zone 21 (gas and dust).These zones include areas in which one

can expect a potentially explosive atmosphere of gases, vapours or mists to occur occasionally.

English

16

i

!

!

(in accordance with ATEX guidelines for certified motors)

Explosion-proof compressed air motors

Содержание MRD 12-280

Страница 3: ......

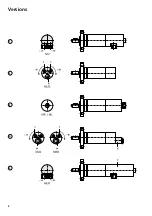

Страница 5: ...Versions 1 2 3 4 5 2 ...

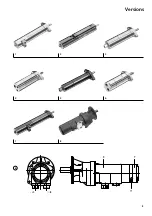

Страница 6: ...Versions 6 6 4 5 7 8 1 2 3 3 ...

Страница 97: ...Notizen Notes 94 ...

Страница 98: ...95 ...