Functions

Leuze electronic GmbH + Co. KG

MLC 530 SPG

39

5.2

Transmission channel changeover

Transmission channels are used to prevent mutual interference of safety sensors which are located close

to each other.

NOTICE

To guarantee reliable operation, the infrared beams are modulated so they can be discerned

from the ambient light. Welding sparks or warning lights, e.g. from passing high-lift trucks,

thereby do not influence the protective field.

With the factory setting, the safety sensor works in all operating modes with transmission channel C1.

Select transmission channel C2 on the receiver:

Ä

Connect pins 1, 3, 4 and 8 of the receiver and switch it on.

ð

The receiver is switched to transmission channel C2. Switch the receiver off and again disconnect the

connection between pins 1, 3, 4 and 8 before switching the receiver back on.

Re-select transmission channel C1 on the receiver:

Ä

Repeat the procedure described above to again select transmission channel C1 on the receiver.

ð

The receiver is switched to transmission channel C1 again.

NOTICE

Faulty function due to incorrect transmission channel!

Select the same transmission channel on the transmitter and corresponding receiver.

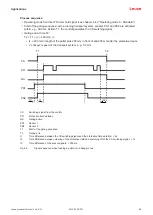

5.3

Operating range selection

In addition to selecting the suitable transmission channels (see chapter 5.2 "Transmission channel

changeover"), the operating range selection also serves to prevent mutual interference of adjacent safety

sensors. At reduced operating range the light power of the transmitter reduces, so that around half of the

nominal range is reached.

Ä

Wire pin 4 (see chapter 8.1 "Pin assignment transmitter and receiver").

ð

The wiring of pin 4 determines the transmitting power and thereby the range (without wiring pin 4 the

reduced operating range is selected).

WARNING

Impairment of the protective function due to incorrect transmitting power!

The light power emitted from the transmitter is reduced through a single channel and without

safety-relevant monitoring.

Ä

Do not use this configuration option for safety purposes.

Ä

Note that the distance to reflective surfaces must always be selected so that no reflection

bypass can occur even at maximum transmitting power (see chapter 7.1.4 "Minimum dis-

tance to reflective surfaces").

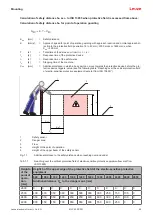

5.4

Signal output

This signal output outputs 24 V if gating is free of errors.

In the event of faulty gating, e.g., if the protective field is not interrupted after 4 s, it flashes.