Testing

Leuze electronic GmbH + Co. KG

MLC 530 SPG

79

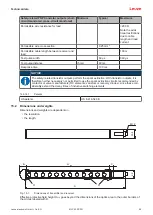

Tab. 10.1:

Checklist for integrator – to be performed prior to the initial start-up and following modifications

Check:

Yes

No

not ap-

plicable

Is the safety sensor operated acc. to the specific environmental condi-

tions that are to be maintained (see chapter 15 "Technical data")?

Is the safety sensor correctly aligned and are all fastening screws and

connectors secure?

Are safety sensor, connection cables, connectors, protection caps and

command devices undamaged and without any sign of manipulation?

Does the safety sensor satisfy the required safety level (PL, SIL, cate-

gory)?

Are both safety-related switching outputs (OSSDs) integrated in the

downstream machine control acc. to the required safety category?

Are switching elements that are controlled by the safety sensor moni-

tored according to the required safety level (PL, SIL, category) (e.g.,

contactors through EDM)?

Are all points of operation near the safety sensor accessible only

through the protective field of the safety sensor?

Are the necessary additional protective devices in the immediate sur-

roundings (e.g., safety guard) properly mounted and secured against

tampering?

If it is possible to be present undetected between the safety sensor and

point of operation: is an assigned start/restart interlock functional?

Is the command device for unlocking the start/restart interlock mounted

in such a way that it cannot be reached from within the danger zone

and so that the complete danger zone can be seen from the installation

location?

Has the maximum stopping time of the machine been measured and

documented?

Is the required safety distance maintained?

Does interruption with a test object intended for this purpose cause the

dangerous movement(s) to stop?

For protective fields with different resolution:

Have each of the areas with different resolution been tested with a suit-

able test object?

Is the safety sensor effective during the entire dangerous move-

ment(s)?

Is the safety sensor effective in all relevant operating modes of the ma-

chine?

Is start-up of dangerous movements reliably prevented if an active light

beam or the protective field is interrupted with a test object intended for

this purpose?

Were distances to reflective surfaces taken into account during config-

uration and no reflection bypasses subsequently detected?

Are notices for regular testing of the safety sensor legible to the opera-

tor and are they located in a highly visible location?

Are changes to the safety function (e.g. blanking, protective field

switchover) not easy to achieve through tampering?