Mounting

Leuze electronic GmbH + Co. KG

MLC 530 SPG

65

For larger protective field heights > 900 mm, the use of the BT-2SB10 swiveling mounting brackets is rec-

ommended (see chapter 16 "Order guide and accessories"). For increased mechanical requirements, these

are also available as vibration-damped version (BT-2SB10-S). Depending on the installation situation, envi-

ronmental conditions and protective field length (> 1200 mm), other mounting brackets may also be neces-

sary.

7.2.6

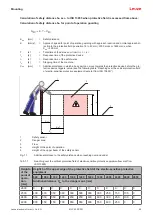

One-sided mounting on the machine table

The safety sensor can be mounted directly on the machine table via an M5 screw on the blind hole in the

end cap. On the other end, a BT-2HF swivel mount can be used, for example, so that turning movements

for alignment are possible despite the fact that the sensor is mounted on one side. The full resolution of the

safety sensor is thus preserved on all points of the protective field down to the machine table.

Fig. 7.10:

Mounting directly on the machine table

WARNING

Impairment of the protective function due to reflections on the machine table!

Ä

Make sure that reflections on the machine table are prevented reliably.

Ä

After mounting and every day after that, check the detection capability of the safety sensor

in the entire protective field using a test rod (see chapter 10.3.1 "Checklist – periodically by

the operator").