Operation

22 / 52

1.0

Vento

®

Press the

+

key to start the residual discharge.

It is possible to cancel the residual discharge whilst in progress by pressing

the

+

key.

Return to operating mode by pressing the

-

or Auto key.

m y

i g

Y

E

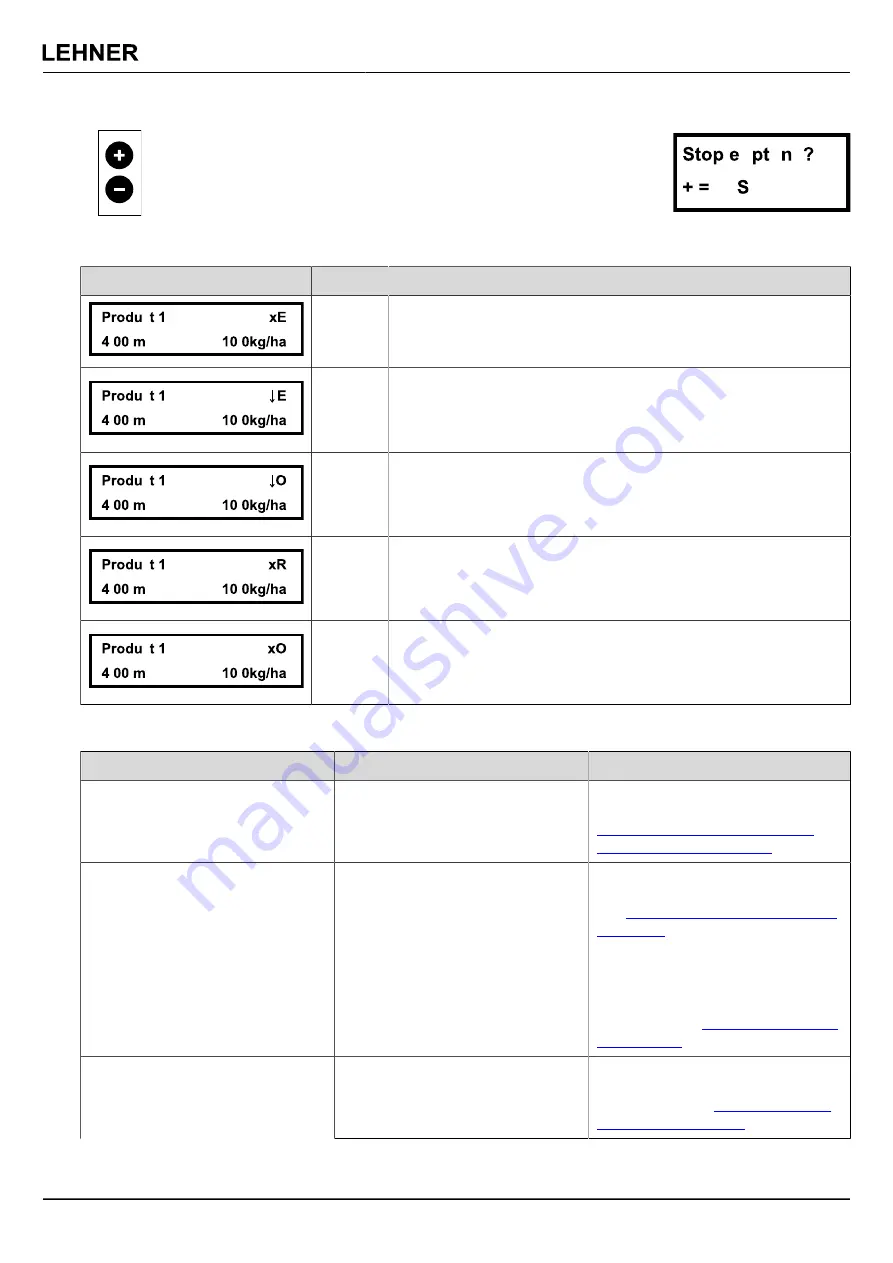

3.10 Error message

Message on the display:

Explanation:

.

c

.

xE =

The 7-pin plug is not connected to the control panel.

.

c

.

↓E =

↑

The 7-pin plug is connected to the control panel, but there is no

speed signal.

Down arrow =

Hydraulics lowered.

Up arrow =

Hydraulics raised.

.

c

.

O =

O circulating =

Means that the speed is too slow (slower than 1.5

km/h).

O circulating and flashing =

The speed is OK (faster than 1.5

km/h).

.

c

.

xR =

x =

No lifting gear magnetic sensor is connected to the control

panel.

R =

No wheel sensor is connected to the control panel or wheel

sensor plugged in but no signal from the sensor.

.

c

.

xO =

x =

No lifting gear magnetic sensor is connected to the control

panel.

O circulating =

No signal from the wheel sensor or speed is too

slow (slower than 1.5 km/h).

3.11 Troubleshooting

Error

Possible cause

Action to take

Output rate excessive/insufficient

Incorrect settings

Perform a calibration test, enter

the correct value and confirm, see

Chapter 3.4.8, "Spreading tables

Poor continuous flow, output rate

too low or rotary feeder shaft does

not turn

Spreading material contaminat-

ed or clumpy, foreign bodies in the

spreading material hopper (e.g.

packaging material)

Check the spreading material (re-

move through the discharge hatch,

see

Chapter 4.2, "Spreading materi-

).

Do not use spreading material with

impurities or clumps.

Check the hopper and rotary feed-

er shaft for contamination, clean if

Rotary feeder shaft does not turn

Hopper, rotary feeders or brushes

heavily contaminated

Check hopper, rotary feeders or

brushes for contamination and clean

if necessary, see

.