6 | Function description

Editing the soldering profile in the [Profile management] tab and changing it permanently

Confirm

Select a profile name

Cancel

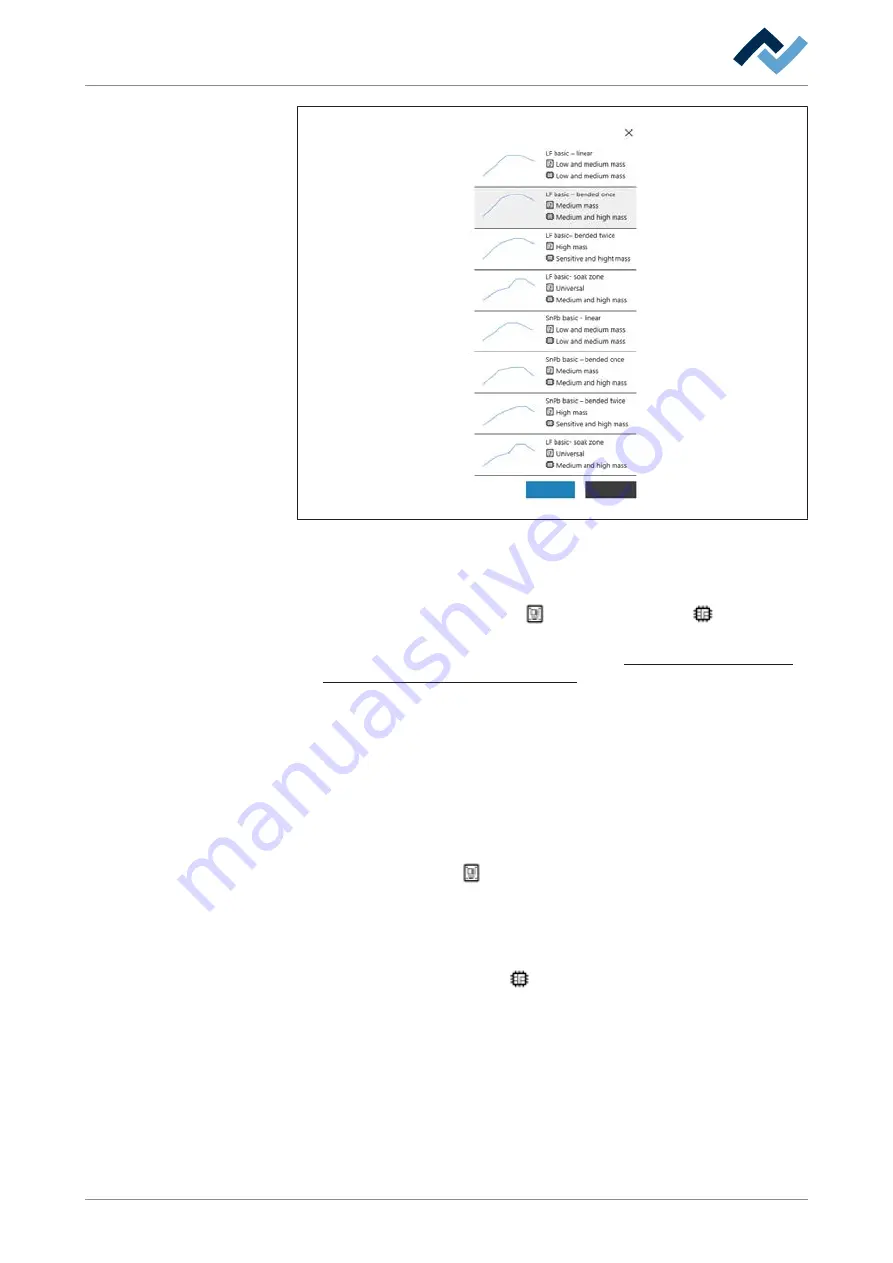

b) Among the eight templates available, select the profile template that best

matches your new soldering profile and click on [Confirm]. The available tem-

plates have been defined based on actual applications. They show the temper-

ature profile as a curve, while the two rows after the soldering profile name

define the properties of the PCB

and of the component

. If necessary,

you may then adjust the selected profile template to your specific soldering

process. With regard to this, please also read the The [Information] tabulator

under the [User management] tabulator [

ð

Row 1: Soldering profile names. The soldering templates are always identi-

fied as “basic”.

“LF” means “lead free”.

“SnPB” means tin-lead.

“linear” indicates a uniform heating-up phase.

“bended once” indicates a heating-up curve with one bend.

“bended twice” indicates a heating-up curve with two bends.

“soak zone” indicates a heating phase with reduced heat from T1 to T2, for

the activation of the flux material.

ð

Row 2: PCB name

. This is defined by default when selecting the profile

template. The templates are named “Low and medium mass” for low to

medium PCB mass, “Medium mass” for medium PCB mass and “Hight

mass” for high PCB mass, while “Universal” is suitable for all types of PCB.

If you want, you may rename the PCBs.

ð

Row 3: Component name

. This is defined by default when selecting

the profile template. The templates are named “Low and medium mass”

for low to medium component mass, “Medium and high mass” for medium

to high component mass and “Sensitive and high mass” in case of high-

mass or sensitive components. If you want, you may rename the compon-

ents.

c) Click on the [Confirm] button.

ð

The new profile is added at the end of the profile list.

d) Save the profile with the “floppy disk” button on the soldering profile list.

Ersa GmbH

Operating instructions HR 550 XL EN 3BA00247-01 | Rev. 1

83 / 157

Содержание HR 550 XL

Страница 2: ......

Страница 6: ......

Страница 22: ...2 Technical data PC system requirements Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 22 157...

Страница 153: ...9 Spare and wear parts Spare parts Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 153 157...

Страница 156: ...10 Annex EC Declaration of Conformity Ersa GmbH Operating instructions HR 550 XL EN 3BA00247 01 Rev 1 156 157...

Страница 157: ......