8. - Instructions for work

HR4004D-4504D

61

KN208JGB_C

Power harrow

8.3

Machine use

-

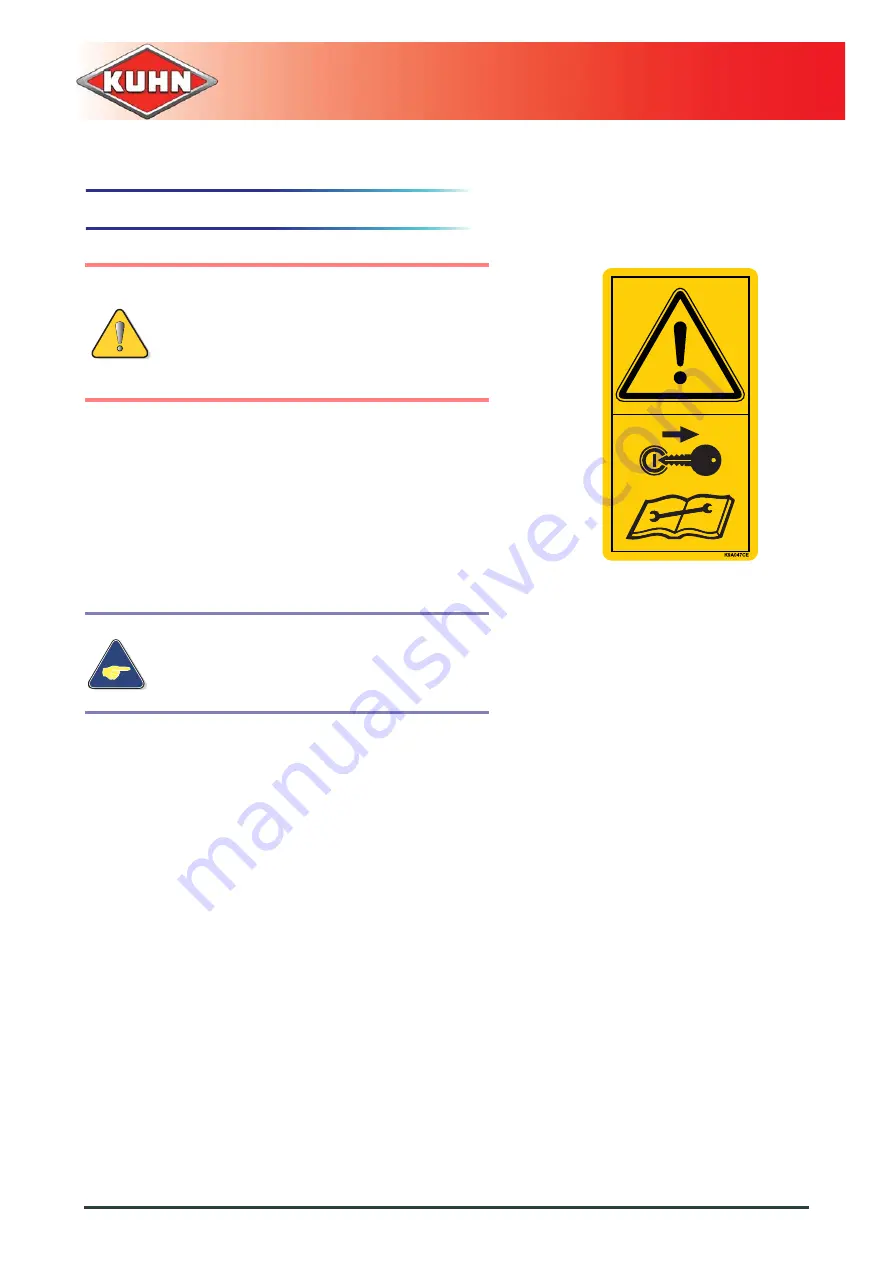

Before leaving the tractor or before

adjusting, maintaining or repairing the

machine, disengage the PTO drive, turn off

the engine, remove ignition key and wait

until all moving parts have come to a

complete stop and apply park brake.

- Lower the machine until the blades are at a

distance of 100-150 mm (3.9’’-5.9’’) with regards to

the ground.

- Engage tractor PTO drive before working with the

machine.

Engaging the machine in the ground before

engaging the tractor PTO can lead to

excessive power requirement and trigger the

torque limiter.

- Lower the machine progressively while on the

move.

- Do not disengage PTO and do not stop tractor

before having lifted the machine from the ground.