3 - 6

Chapter 3. Troubleshooting

Identifying Print Defects

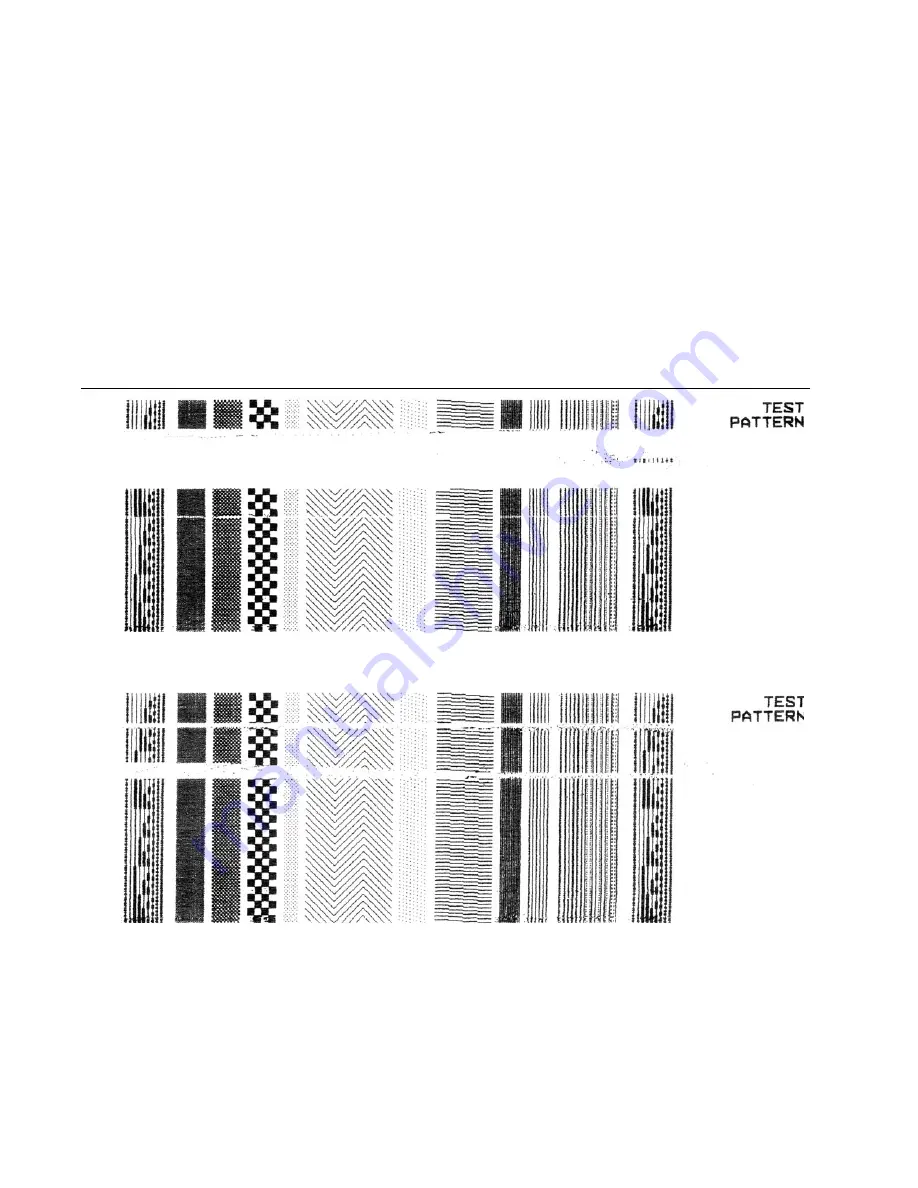

Serious Raggedness

Dried ink buildup that is not promptly removed,

or contamination deposits on the orifice plate will steadily reduce the print

window until it eventually becomes impossible to get good print.

Swabbing and print window adjustment should eliminate serious

raggedness (see the top pattern in Figure 3.4). If cleaning and printhead

adjustment fail to correct the problem, replace the printhead.

Buildup / Missing Print

After a shut down, or during intermittent

operation, dried ink residue builds up and causes a defect that resembles

phase defect. Figure 3.4 shows this defect on a series of four pieces

printed at 130 volts and 41 phase counts. The defect may diminish during

operation as the dried ink dissolves. A milder form of buildup causes

‘startup raggedness’ or generally poor print quality without missing print,

usually on the first few pieces printed. Scheduled cleaning (wiping the

catch pan and eyelid seal) should reduce or eliminate buildup, missing

print, and startup raggedness.

Figure 3.4

Buildup-caused missing print, sample test pattern

Содержание VERSAMARK DP7122

Страница 1: ...Kodak Versamark Inc KODAK VERSAMARK DP7122Printer Operator s Guide ...

Страница 2: ......

Страница 3: ...KODAK VERSAMARK DP7122 Printer Operator s Guide Block 3 Mod 11 ...

Страница 8: ......

Страница 24: ......

Страница 37: ...3 7 Chapter 3 Troubleshooting Identifying Print Defects Figure 3 4 continued ...

Страница 44: ......

Страница 56: ......

Страница 61: ......

Страница 62: ...0114130 602 0114130 603 Kodak Versamark Inc ...