3. Clean the armature and piston.

If the spring and O-ring are damaged or worn they must be replaced.

4. Reassemble the valve.

5. Open the user's shut-off valve between the machine and the air system.

6. Start the machine and visually check for leaks.

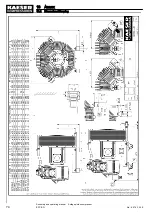

10.13.2 Changing the solenoid valve.

Fig. 29 Changing the solenoid valve.

1

Solenoid valve

2

Fitting

3

Elbow with damper

4

Connecting socket

1. Disconnect the connecting socket from the valve.

2. Unscrew the elbow and damper.

3. Remove the defective valve.

When mounting the solenoid valve make sure the flow direction is correct as indicated by the

arrow on the body.

4. Screw the fitting and damper into the new solenoid valve using sealing tape.

5. Re-install the solenoid valve in the compressed air line.

6. Open the user's shut-off valve between the machine and the air system.

7. Start the machine and visually check for leaks.

10.14 Cylinder head and valves

Material Compressed air for blowing out

Cleaning cloths

Brush

Spares as required

10.14.1 Checking the cylinder head and valves

The condition of the valves can be assessed by measuring the air receiver charging time and com‐

paring this with the charging time when the machine was new.

10 Maintenance

10.14 Cylinder head and valves

No.: 9_5753_04 E

Assembly and operating manual 2-stage piston compressor

EPC-2-G

61

Содержание EPC-2-G Series

Страница 2: ...Original instructions KKW PEPC 1 04 en SBA KOLBEN AGGREGAT 2 STUFIG ...

Страница 6: ...Contents iv Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E ...

Страница 10: ...List of Tables viii Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E ...