DANGER

Compressed air!

➤ Compressed air and devices under pressure can injure or cause death if the contained energy

is released suddenly.

➤ Close shut-off valves or otherwise isolate the machine from the compressed air network to en‐

sure that no compressed air can flow back into the machine.

1. Close the user's shut-off valve between the machine and the air network.

2. Vent the machine via the user's venting valve or the solenoid valve integrated in the machine.

10.13 Solenoid Valve Maintenance

The machine must be isolated from the air system and completely vented before undertaking any

work on the pressure system.

Material Compressed air for blowing out.

Cleaning rags.

Acid-free grease (e.g. Shell Retinax)

Replacement part

Precondition The mains disconnecting device is switched off.

The disconnecting device is locked in the off position.

A check has been made that no voltage is present.

Machine is fully vented (no pressure).

The user's shut-off valve between the machine and the air network is closed.

10.13.1 Clean the solenoid valve

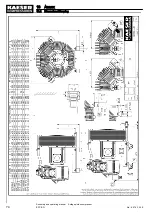

Fig. 28 Cleaning the solenoid valve

1

Solenoid valve

2

Screw

3

Solenoid

4

Armature

5

Spring

6

Piston

7

Body

8

Connecting socket

9

Arrow showing flow direction

1. Disconnect the connecting socket from the valve.

2. Undo the screw and carefully remove the coil.

10 Maintenance

10.13 Solenoid Valve Maintenance

60

Assembly and operating manual 2-stage piston compressor

EPC-2-G

No.: 9_5753_04 E

Содержание EPC-2-G Series

Страница 2: ...Original instructions KKW PEPC 1 04 en SBA KOLBEN AGGREGAT 2 STUFIG ...

Страница 6: ...Contents iv Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E ...

Страница 10: ...List of Tables viii Assembly and operating manual 2 stage piston compressor EPC 2 G No 9_5753_04 E ...