JOHNSON CONTROLS

228

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

SECTION 7 - OPERATION

Remote Current Limit Reset is only possible if the op-

tion is enabled by both the OPTIONS key selection and

in the factory programmable password protected Unit

Setup Mode.

Remote ISN Current Limit Setpoint

The ISN Current Limit Setpoint can be set via the ISN

comms. The control panel will only accept a Current

Limit Setpoint from the ISN if the control panel is in

Remote Control Mode (under the OPTIONS key). If

the control panel is in Local Control Mode, the ISN

setpoint will be ignored. The minimum and maximum

allowable values will be the same as the minimum and

maximum allowable reset values for the Current Limit

Setpoint under the PROGRAM key. If these values are

exceeded, the minimum or maximum value will be

used.

Contact a local Johnson Controls ISN Representative

for details on ISN controls and capabilities.

Remote Current Limit Reset

The Current Limit Setpoint can be set or reset via the

Remote Current Limit analog input. A zero signal in-

put (0% input) equates to the maximum current limit

setpoint as defined under the PROGRAM key Cur-

rent Limit Setpoint. A full scale signal input (100%

input) equates to the minimum current limit setpoint

as defined under the PROGRAM key Current Limit

Setpoint. The current limit value is linear and may be

adjusted anywhere between the maximum and mini-

mum points of 0 (no offset) and 100% (max. current

limiting).

This input may be used either in Local or Remote Con-

trol Mode. This input will be ignored if the Remote

Current Limit is disabled under the OPTIONS key.

Once a change to the input is registered, a timer is set

to the value of the Remote Inputs Service Time as pro-

grammable under the Unit Setup Mode at the factory

for the default value of 15 minutes. The low limit is 5

minutes and the high limit is 60 minutes. The Remote

input will be ignored until this timer expires. The tim-

er assures that rapid changes in a remote reset signal

don’t result in poor temperature control or excessive

compressor cycling. In most instances, this timer will

not need to be changed, since reset more often than 15

minutes will create problems with chilled liquid tem-

perature control. Factory Service should be contacted

if a timer change is required.

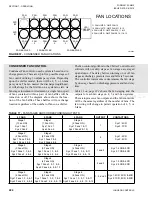

Control board jumper JP5 must be positioned correctly

to receive either a voltage (0 to 10VDC or 2 to 10VDC)

or current (0 to 20mA or 4 to 20mA) signal. Place the

jumper in the “V” position for a voltage signal or mA

for a current signal

(See Figure 27 on page 178 and

. The software must be con-

figured under the OPTIONS key for the type of input

signal to be used.

The minimum current limit setpoint is achieved at ei-

ther 10VDC or 20mA. Sending the minimum signal

(0VDC, 2VDC, 0mA, or 4mA based on the OPTIONS

key setting) causes the current limit to revert back to its

maximum value.

0 through Reset Input

A 0VDC signal sets the current limit to the maximum

value. A 10VDC signal sets the current limit to the

minimum value. The current limit is ramped linearly

between these limits as the input varies between 0VDC

and 10VDC. In order for this input to work properly,

the Remote Current Limit must be programmed for

0 through 10VDC input (OPTIONS key) and Chiller

Control Board jumper JP5 placed in the “V” position.

2 through 10VDC Reset Input

A 0 - 2VDC signal sets the current limit to the maxi-

mum value. A 10VDC signal sets the current limit to the

minimum value. The current limit is ramped linearly

between these limits as the input varies between 2VDC

and 10VDC. In order for this input to work properly,

the Remote Current Limit must be programmed for

2 through 10VDC input (OPTIONS key) and Chiller

Control Board jumper JP5 placed in the “V” position.

0 through 20mA Reset Input

A 0mA signal sets the current limit to the maximum

value. A 20mA signal sets the current limit to the mini-

mum value. The current limit is ramped linearly be-

tween these limits as the input varies between 0mA

and 20mA. In order for this input to work properly,

the Remote Current Limit must be programmed for 0

through 20mA input (OPTIONS key) and Chiller Con-

trol Board jumper JP5 placed in the “mA” position.

4 through 20mA Reset Input

A 4mA signal sets the current limit to the maximum

value. A 20mA signal sets the current limit to the mini-

mum value. The current limit is ramped linearly be-

tween these limits as the input varies between 4mA

and 20mA. In order for this input to work properly,

the Remote Current Limit must be programmed for 4

through 20mA input (OPTIONS key) and Chiller Con-

trol Board jumper JP5 placed in the “mA” position.

Содержание YCIV0157

Страница 18: ...JOHNSON CONTROLS 18 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SAFETY SYMBOLS THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 104: ...JOHNSON CONTROLS 104 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SECTION 6 TECHNICAL DATA Panel Layout 2 Compressor Models ...

Страница 105: ...JOHNSON CONTROLS 105 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 115: ...JOHNSON CONTROLS 115 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 119: ...JOHNSON CONTROLS 119 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...