JOHNSON CONTROLS

172

FORM 201.23-NM2

ISSUE DATE: 3/9/2015

SECTION 6 - TECHNICAL DATA

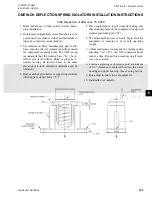

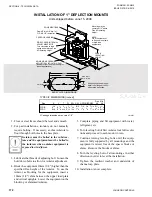

1. Floor or steel frame should be level and smooth.

2. For pad installations, isolators do not normally

require bolting. If necessary, anchor isolators to

floor through bolt holes in the base plate.

Isolators must be bolted to the substruc-

ture and the equipment must be bolted to

the isolators when outdoor equipment is

exposed to wind forces.

3. Lubricate the threads of adjusting bolt. Loosen the

hold down bolts to allow for isolator adjustment.

4. Block the equipment 10mm (1/4") higher than the

specified free height of the isolator. To use the

isolator as blocking for the equipment, insert a

10mm (1/4") shim between the upper load plate

and vertical uprights. Lower the equipment on the

blocking or shimmed isolators.

5.

Complete piping and fill equipment with water,

refrigerant, etc.

6.

Turn leveling bolt of first isolator four full revolu

-

tions and proceed to each mount in turn.

7. Continue turning leveling bolts until the equip-

ment is fully supported by all mountings and the

equipment is raised free of the spacer blocks or

shims. Remove the blocks or shims.

8. Turn the leveling bolt of all mountings in either

direction in order to level the installation.

9. Tighten the resilient washer and underside of

channel cap plate.

10. Installation is now complete.

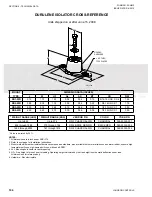

Illustration shows single spring CIP-B or CIP-C mount.

HCL

SBC

Slot Width - SW

HCW

MAX BOLT

DIA. - MBD

BASE PLATE DIMENSIONS

NON-SKID NEOPRENE

ACOUSTICAL ISOLATION PAD

(Bolting to floor is not necessary for

indoor applications)

All springs have additional

travel to solid equal to 50%

of the rated deflection.

A

L

FREE &

OPERATING

HEIGHT

T

W

FERROUS HOUSING

SIDE ACCESS INTERNAL

ADJUSTMENT BOLT

Turn clockwise to load

spring and maintain Free

& Operating Height.

Dowel Pin is 3/8" dia. for

CIP-A & 1/2" thereafter

Mounting may be

operated 1/2" above

Free & Operating

Height.

NOTE-

CIP Mounts are not

to be used in seismic

or wind load

applications.

EQUIPMENT BASE

TYPE CIP DIMENSIONS (inches)†

†Casting dimensions may vary ±1/8"

Size

A

L

T

W SW

HCL HCW MBD SBC

Free

Ht.

CIP-B

8

/4

/2

/16

8

CIP-C

6

/8

/16

/8

5

1

1

7

7

3

3

/8

1

6

/4

3

/

5

/4

3

8

/8

7

/16

9

2

/4

3

3

/2

1

/2

/4

1

1

6

7

/2

/4

1

3

1

1

/4

/8

1

7

7

7

Min

Ht.

5

/4

1

6

/4

3

6

LD10577

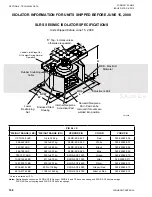

Units shipped before June 15, 2008

INSTALLATION OF 1" DEFLECTION MOUNTS

Содержание YCIV0157

Страница 18: ...JOHNSON CONTROLS 18 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SAFETY SYMBOLS THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 38: ...JOHNSON CONTROLS 38 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 42: ...JOHNSON CONTROLS 42 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...JOHNSON CONTROLS 50 FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

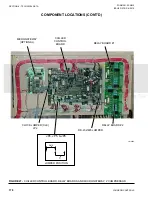

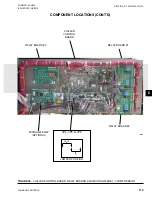

Страница 104: ...JOHNSON CONTROLS 104 FORM 201 23 NM2 ISSUE DATE 3 9 2015 SECTION 6 TECHNICAL DATA Panel Layout 2 Compressor Models ...

Страница 105: ...JOHNSON CONTROLS 105 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 115: ...JOHNSON CONTROLS 115 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 119: ...JOHNSON CONTROLS 119 SECTION 6 TECHNICAL DATA FORM 201 23 NM2 ISSUE DATE 3 9 2015 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 333: ...JOHNSON CONTROLS 333 FORM 201 23 NM2 ISSUE DATE 3 9 2015 NOTES ...