VIS-CAM Systems

34

System Set-Up

1. A vehicle that can be temporarily parked on the road

2. A plate that is:

a. typical in size and color for the site

b. clean, flat and in “like new” condition

3. An adjustable plate stand that allows the plate to be mounted in a vertical plane, at various

heights above the road, and at variable roll angles. The stand must allow the plate to be placed

at both the nominal plate height and the minimum expected plate height. The stand must also

allow the plate to be rolled at least + or – 10 degrees from horizontal but held firmly in place

once a specific roll angle is selected. The stand should be heavy enough so that the wind will

not blow it over or move it.

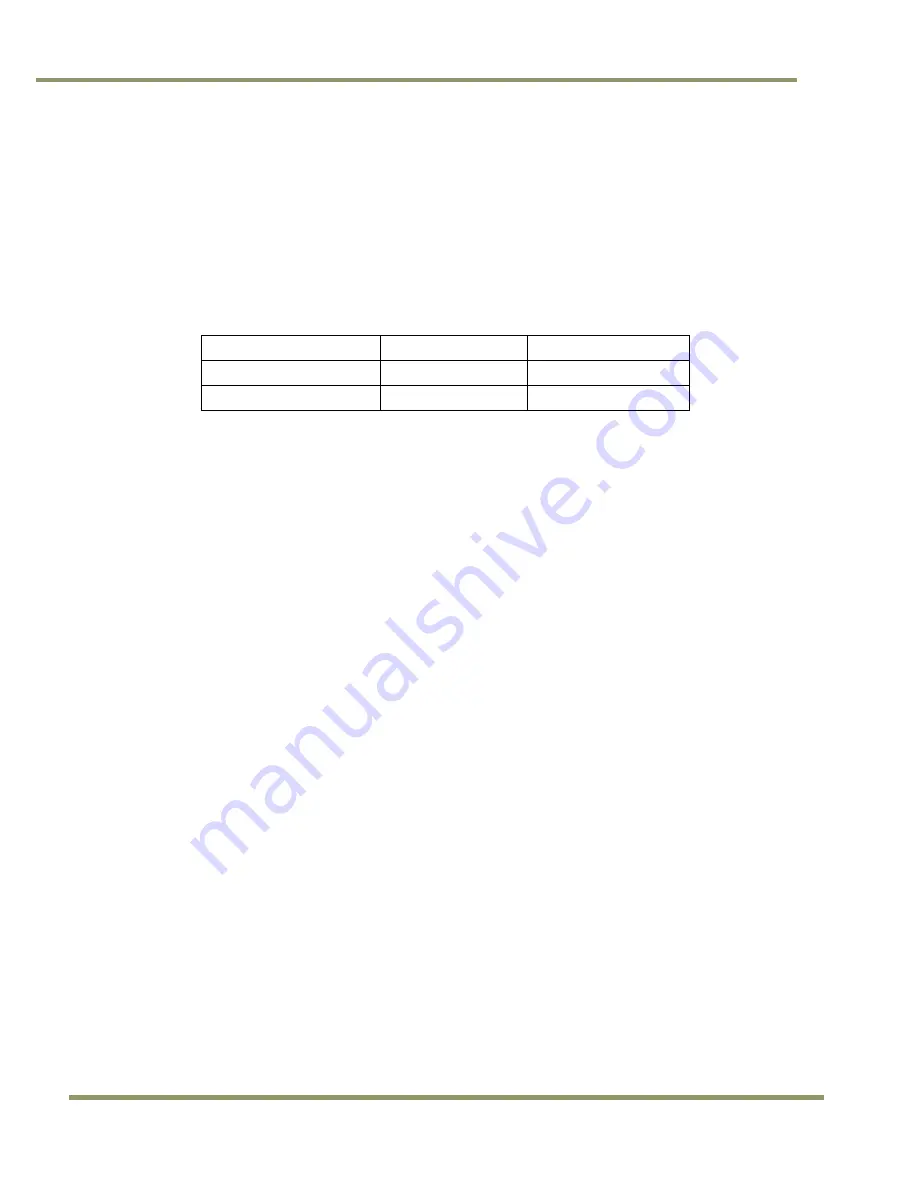

Table 11

Typical minimum plate heights and nominal plate heights:

Plate Height

Front of Vehicle

Back of Vehicle

minimum (bottom edge)

8in or 20cm

15in or 38cm

nominal (middle)

16in or 40cm

24in or 60cm

4.1.3

Select the Camera to Align

•

If the site employs a single camera per lane, then you can choose any lane to start the

alignment procedure.

•

If the site employs multiple cameras regularly spaced across a roadway to provide continuous

fieldof- view coverage from edge to edge, select one of the cameras at either edge of the

roadway to be the first camera to align.

•

Align all remaining cameras in order from the first camera aligned to the last camera at the

other side of the roadway. The next camera aligned is always the one adjacent to the camera

most recently aligned.

4.1.4

Validate the Installation Geometry

The VIS cameras and vehicle trigger line should have been installed at the locations agreed to by you and JAI.

Typically JAI utilizes a specially developed Excel worksheet to confirm the suitability of the equipment

placement at the site from an image processing perspective. See Figure for an example worksheet. However,

equipment is often not located where the worksheet specifies. It is therefore imperative that the actual

equipment layout at any given site be measured to verify that the cameras and trigger are located at the

desired locations relative to each other. If necessary, move the camera/trigger positions until the distances

required in the worksheet are met. If it is not possible to move the equipment to the required locations, then

the impact of any changes to the subsequent image processing must be assessed. Enter the actual camera

locations into the Input section of the JAI worksheet and then note the changes in the Results section. If there

are any questions about the suitability of a specific camera/trigger layout, contact your JAI representative for

advice.

4.1.5

Edit the alignment settings on the Setup Computer

In order to carry out the alignment properly, the ENSetup program has to be configured with two values from

the worksheet. See the ENSetup Program User’s Guide (Video Window Setup section) for details on changing

Video Window properties.

Using the ENSetup program, make sure the “tilt line” and “plate num cols” items on your Portable Setup

computer are exactly the same as the measurements, including the proper plate size parameters measured in

Section 4.1.4, “Validate the Installation Geometry,”. All other camera settings should already be correct for

the site installation, but it is a good idea to verify that this is true before proceeding. The Setup Computer is

now properly configured to support lens adjustments and camera aiming.

Содержание VIS-CAM System

Страница 1: ...VIS CAM System Vehicle Imaging Subsystem Document Version 10436 Document P N E...

Страница 2: ......

Страница 12: ...VIS CAM Systems xii List of Tables...

Страница 20: ...VIS CAM Systems 8 Preparing for Installation Figure 5 VIS 300 U S Camera options chart...

Страница 21: ...Preparing for Installation 9 VIS CAM Systems Figure 6 VIS 350 U S Camera options chart...

Страница 22: ...VIS CAM Systems 10 Preparing for Installation Figure 7 VIS 400 U S Camera options chart...

Страница 23: ...Preparing for Installation 11 VIS CAM Systems Figure 8 VIS 500 U S Camera options chart...

Страница 24: ...VIS CAM Systems 12 Preparing for Installation Figure 9 VIS 300 European Camera options chart...

Страница 25: ...Preparing for Installation 13 VIS CAM Systems Figure 10 VIS 350 European Camera options chart...

Страница 26: ...VIS CAM Systems 14 Preparing for Installation Figure 11 VIS 400 European Camera options chart...

Страница 27: ...Preparing for Installation 15 VIS CAM Systems Figure 12 VIS 500 European Camera options chart...

Страница 92: ...VIS CAM Systems 80 Appendix B Figure 90 Lane controller setup...

Страница 100: ...VIS CAM Systems 88 Appendix E Figure 98 Operation configuration of Serial port 1...

Страница 110: ......

Страница 111: ......