4

Concord CXA/H

- Installation and Servicing

GENERAL

Boiler Size

Cold Feed

Open Vent

CXA 40/H - 50/H

3/4

"

1"

CXA 60/H -120/H

1"

1

1/4

"

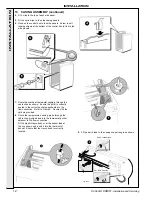

Sealed system filling point - refer to Frame 8

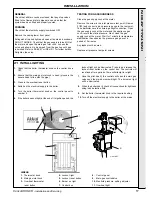

Flow and return connections are 2" BSP.

A 1" BSP tapping is provided in the redundant return flange for

the cold feed or expansion vessel connection.

Safety Valve

A safety valve must be sized and fitted in accordance with BS.

6644 for every type of system. The valve should be set at 0.7

bar (10 lb/in.

2

) above the operating pressure in the boiler. The

maximum safety valve setting is 0.7 bar (10 lb/in.

2

) above the

maximum design operating pressure of 6 bar (87 lb/in.

2

).

Cold Feed/Open Vent

The independent cold feed and the open vent must comply

with BS. 6644 and be of the following minimum size.

1

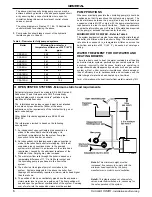

WATER CONNECTIONS

GAS CONTROLS

Control is by automatic ignition of intermittent pilot; once the

presence of a flame has been proved the single (or double) main

gas valves open to give full heat input. The mains voltage supply

is via a terminal plug connection at the control box.

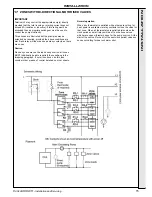

ELECTRICAL CONTROLS

The boiler is supplied with 2 printed circuit boards; Board

S4561B1054 is the ignition board containing the flame proving

logic and the on-board spark generator. Board W4115A1020

contains the electronic thermostat and the pump overrun timer. A

preset overheat thermostat is also fitted. The control box displays

neons indicating boiler status as follows:

z

Boiler on

z

Lockout

z

Overheat

A 4 minute anticycle delay is built in to the controls to prevent rapid

cycling.

FROST PROTECTION

Frost protection is incorporated in the boiler as long as there is a

permanent live supply wired to terminal L1 on the terminal plug-in

connection at the control box and the boiler thermostat knob is not

switched to off.

If the temperature sensed by the boiler thermostat falls to about

5

o

C the boiler will fire until the temperature reaches 18

o

C. Note

that this is designed to protect the boiler and may not necessarily

protect the remote parts of the system.

OPTION KITS

Remote indication kit

This kit gives the facility of remote indication of the boiler status.

Pressure gauge kit

In addition to the above control kit, an optional pressure gauge

is also available for the range of boilers. Details for fitting are

included with the pressure gauge.

Downdraught thermostat kit

This kit is optional when used on a single CXA/H installation, but

mandatory when used on a multiple boiler installation.

DUTY

The range of boilers is suitable for: Combined indirect pumped

domestic hot water

and

central heating systems; Independent

indirect pumped domestic hot water

or

central heating systems.

Fully pumped systems may be open vented or sealed.

The range of boilers is NOT suitable for:

1.

Gravity DHW systems.

2.

Gravity heating systems.

3.

Direct domestic hot water supply.

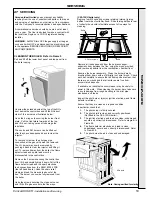

WATER CIRCULATION SYSTEM

Due to the compact nature of the boiler the heat stored within the

castings at the point of shutdown of the burner must be dissipated

into the water circuit in order to avoid the overheat thermostat tripping.

In order to allow pump operation after burner shutdown the boiler

control box incorporates a pump overrun facility which operates for

approximately 6 minutes after burner shutdown and, in order to

make use of this, the pump must be wired to the appropriate

terminal L2 (pump) in the boiler control box.

1.

The minimum flow rate as given in Table 4 must be

maintained whenever the boiler is firing and during the pump

overrun period.

2.

During the period of pump overrun there must be an open

circuit of adequate water volume and/or load. The minimum

size of this circuit is given by the use of Graph 1.

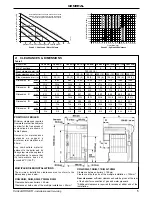

Examples shown on Graph 1

a.

For the

CXA 90/H and CXA 100/H

the minimum circuit during

pump overrun could be a load of 6 kW with a volume of 31

litres or any other combination given by the relevant line.

b.

For the

CXA 70/H and CXA 80/H

the minimum circuit during

pump overrun could be a load of 2 kW with a volume of 45

litres or any other combination given by the relevant line.

Содержание Concord CXA 40/H

Страница 1: ......