10

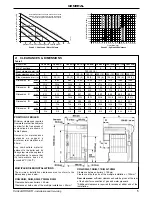

Concord CXA/H

- Installation and Servicing

INSTALLATION

7

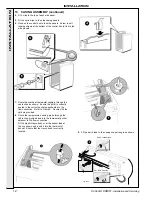

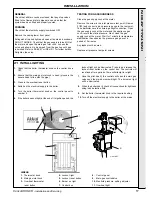

PACKAGING AND BOILER REMOVAL

1.

Remove the casing carton and outer packaging

frame.

2.

Remove the casing pack support frame.

3.

Remove the distributor tube pack, controls package

and installation pack.

4.

Remove the 2" BSP steel handling bars from the

installation pack.

5.

Remove the 4 base bolts holding assembly to the

packaging base.

6.

Remove the wood screws securing the front cross

member on the packaging base.

7.

Remove the gas cock by unscrewing the union and

screw in the handling bars into the 2 front tappings.

Protect the exposed inlet gas union from ingress of

dirt.

8.

Knock out the front spacing blocks from the packaging

base, ensuring that the boiler assembly is supported,

using 2" BSP handling bars.

9.

Using the handling bars, manoeuvre the boiler forwards

on the packaging base and slide over collapsing base on

to the floor.

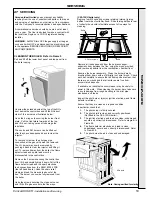

Note.

Before manoeuvring the boiler into its final position

see Frame

8

c.

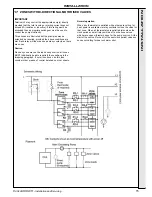

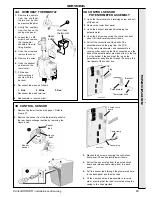

Fit the 2 thermostat pockets. Refer to Frame 9.

Note.

Frame 9 shows the relationship between

the overheat thermostat and the flow tapping.

d.

Complete the water connections by plugging the

2 front top tappings with the 2" BSP plugs

provided.

1.

Fit the distributor tube (supplied with the boiler) into

one of the return connection. That is one of the rear

lower ports - refer to Frame 5.

Fit the flange, using the M10 x 35mm screws and

washers provided.

Ensure that the notch in the tube flange sits correctly

into the groove on the section and that the 2 sealing

gaskets are correctly assembled on the tube.

2.

Fit the 1" tapped flange to the other lower rear

connection, using the gasket and M10 x 25mm

screws and washers provided.

3.

Temporarily screw the 2 handling bars (2" pipe) into

the top tappings and manoeuvre the boiler into

position.

4.

Complete the system connections, using suitable

jointing compound, as follows:

a.

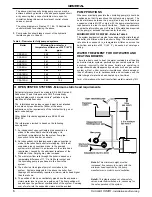

The flow connection may be made to either of the

rear top tappings (either at the same side as the

return or opposite the return).

To avoid air locks, any reduction in pipe size must

be made in the vertical plane or achieved by using

eccentric bushes.

b.

The 1" tapping in the redundant return flange may

be used for the cold feed on an open system or

connection of a pressure vessel if on a sealed

system.

If not required for this purpose it should be

plugged.

8

BOILER ASSEMBLY

INST

ALLA

TION

Содержание Concord CXA 40/H

Страница 1: ......