8

Concord CXA/H

- Installation and Servicing

GENERAL

Position ventilation grilles to avoid the risk of accidental

obstruction by blockage or flooding. If further guidance on

ventilation is required then consult BS.6644 and BS.5440:2.:

2000

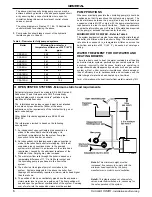

AIR SUPPLY BY MECHANICAL VENTILATION

The supply of air by mechanical means to a space housing the

boiler should be by mechanical inlet with natural or

mechanical extraction. Mechanical extract ventilation with

natural inlet must NOT be used.

Where a mechanical inlet and a mechanical extract system is

applied, the design ventilation flow rates should be as in Table

4 of BS.6644.

The requirements for air supply by mechanical ventilation are

given in BS.6644.

Note.

For mechanical ventilation systems an automatic control

should be provided to cause safety shutdown or lockout of the

boiler(s) in the event of failure of air flow in either inlet or extract

fans.

IMPORTANT.

The use of an extractor fan in the same room as

the boiler (or in an adjacent, communicating room) can, in

certain conditions, adversely affect the safe operation of the

boiler. Where such a fan is already fitted (or if it is intended to

fit an extractor fan after installation of the appliance) the advice

of the Gas Region should be obtained.

Tests for spillage of products from the draught diverter when

the extractor fan is running and all doors and windows are shut

should be carried out after installation. If spillage is detected,

the area of permanent ventilation must be increased.

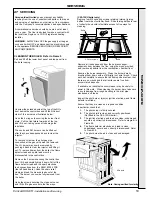

CHIMNEY SYSTEM

To ensure the safe and satisfactory operation of the boiler the

chimney system (which may be common or individual, in the

case of twin or multiple boiler installations) must be capable of

the complete evacuation of combustion products at all times.

The effective height of the chimney terminal(s) above the boiler

outlet(s) must ensure sufficient buoyancy to overcome the

resistance of the bends, tees and runs of the flue pipe involved

and shall terminate in a down draught free zone. The number of

bends and lengths of horizontal flue pipe used should be kept to

a minimum in order to reduce gas flow resistance.

Compliance with the recommendations made in BS.6644,

IGE UP/10 Installation of Gas Appliances in Industrial and

Commercial Premises and the Third Edition of the 1956 Clean

Air Act Memorandum’ should be strictly observed where

applicable.

The chimney design should avoid the formation of excessive

quantities of condensate. For this reason it is recommended

that all chimneys are insulated and lined. In the case of brick or

similar structures a stainless steel rigid or flexible flue liner

(grade 304/316) may be used in conjunction with a 50 mm

(minimum) thick layer of vemiculite or perlite granules between

the liner and the inner skin of the chimney body. Liners should

be sealed at both top and bottom.

As the

Concord CXA/H range

of boilers is supplied complete

with an integral draught diverter, a diverter MUST

NOT

be fitted

within the chimney system.

Drainage points positioned at the bottom of all vertical chimney

sections should be provided. Drain pipes should be no less

than 25 mm I.D., manufactured from acid condensate resistant

material such as stainless steel and be positioned so that pipe

runs and discharge points are not subject to the effects of frost

and that flue gases cannot leak into the boiler room.

Care should be taken to ensure the specification of the chimney

is suitable for the application by reference to the manufacturers

literature.

Caradon Ideal Limited

can offer advice on the design

of suitable chimney systems.

GAS SUPPLY

If there is any doubt regarding the capacity of the gas meter, the

available gas pressure, the adequacy of existing service pipes

or the size required for new service pipes then the advice of the

gas region should be requested.

Installation pipework should be fitted and tested for gas

soundness in accordance with BS. 6891;

IGE-UP-1 for small installations

IGE-UP-2 for large installations.

The local gas region must be consulted if it is necessary to

employ a gas pressure booster.

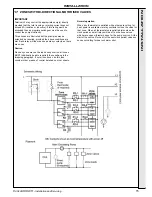

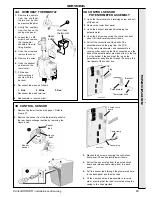

ELECTRICAL SUPPLY

WARNING.

This appliance must be efficiently earthed.

A 230 V - 50 Hz mains supply is required, fused at 5 amps.

Wiring external to the appliance MUST be in accordance with the

I.E.E. (BS. 7671) Wiring Regulations and any local regulations

which apply.

For details of connections refer to Frame 14.

VENTILATION

Safe, efficient and trouble-free operation of open flued gas

boilers is vitally dependent on the provision of an adequate

supply of fresh air to the room in which the appliance is

installed. Ventilation by grilles communicating to the outside

air is required. The minimum free area and required

positioning of these grilles must be in accordance with Tables

5 & 6.

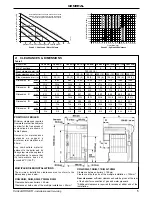

Table 5 (to BS5440)

CXA 40/H-60/H boilers installed in a room or internal space

Boiler size

Air vent free area cm

2

40

202

50

247

60

304

This air vent shall be direct to outside air or to a room or

internal space itself with an air vent to outside air of the same

size.

Table 6 (to BS6644)

CXA 70/H-120/H boilers

Required area (cm

2

) per kW of total rated input (net)

Boiler room

Enclosure

Low level (inlet)

4

10

High level (outlet)

2

5

Note: Where a boiler installation is to operate in summer

months (e.g. DHW) additional ventilation requirements

are stated, if operating for more than 50% of time (refer

to BS6644).

157290-3.pmd

11/7/2005, 11:09 AM

8

Содержание Concord CXA 40/H

Страница 1: ......