20

Concord CXA/H

- Installation and Servicing

SERVICING

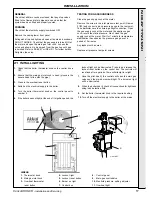

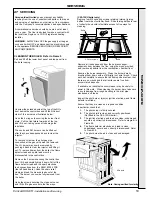

4mm

Pilot burner

Pilot draught

shield

3 - 4mm

Spark gap

Flame detector

electrode

Spark

electrode

Main burner flame ports

Pilot and electrode positions

29 REPLACEMENT OF COMPONENTS - Refer to Frame 5

GENERAL

WARNING.

Always

turn

OFF

the gas supply at the gas

inlet cock and switch

OFF

and

DISCONNECT

the

electricity supply

BEFORE WORKING

on the appliance.

To facilitate the replacement of components, remove and

replace the lower front panel, NOx duct and the burner front

plate as necessary -described under ‘Servicing’.

28 SERVICING - continued

.

Refit the LH burner, ensuring that the flame detector lead is

properly connected. Reconnect both electrode leads at the

S4561B1054 PCB in the control box. Ensure the sleeving passes

through the strain relief clamp before refastening it.

Refit the centre and RH burners. Ensure that care is taken not to

damage the combustion chamber insulation and that the burner

front plate fits beyond the burner retaining returns when it is

refitted.

(CXA 120/H boiler only)

Refit collector hood baffles within collector hood using M5 securing

screws.

Refit the flue clean out cover, NO

X

ducts, control box door, casing

top and front panels.

TESTING AFTER SERVICING

After re-assembly, restore the electricity and gas supplies. Light the

boiler (refer to the Lighting and Operating Instruction Label on the

inside of the casing front panel) and check the gas connections for

tightness, as detailed under ‘Testing for Gas Soundness’ - Frame

20.

Check gas pressures and the gas rate; test as instructed in Frame

22 ‘Manifold Gas Pressure’ and 'Testing’. Adjust any time and

temperature controls to User’s requirements and remember to

reset any time control, which may have been switched off, to the

correct time of day. Refit the lower front panel.

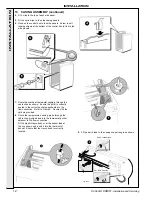

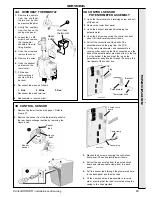

1.

Remove the LH burner as previously described in

Frame 27

2.

Remove the 2 screws securing the control box front

panel, lift it and carefully lower it down.

3.

Remove the flame detector lead and the spark lead

connections from the S4561B1054 PCB in the control

box. Undo the strain relief clamp and pass the

sleeved wires through the grommetted hole in the

back panel.

4.

Remove the spark electrode by undoing the back nut.

Pull off the flame detector lead connection and

unscrew the electrode.

5.

Undo the pilot pipe connection and undo the 2

screws retaining the pilot burner and remove it.

6.

Fit the new pilot burner, ensuring that it faces towards

the front of the burner and that the pilot injector is in

position before connecting the pilot pipe.

7.

Reassemble in reverse order, ensuring that the

spark electrode lead passes through the sleeving

and that the sleeving passes through the strain relief

clamp in the control box before retightening.

30 PILOT BURNER ASSEMBLY

Pilot burner

Pilot draught shield

(Not fitted to CXA 120/H)

Fixing screw (2)

LH burner

Flame detector

electrode

Spark electrode

Backnut

Flame detector

lead

SER

VICING

Содержание Concord CXA 40/H

Страница 1: ......