3-29 ENGINE

◉

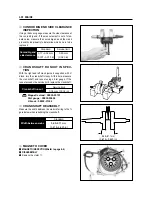

CONROD BIG END SIDE CLEARANCE

INSPECTION

Using a thickness gauge, measure the side clearance at

the conrod big end. If the measurement is out of stan-

dard value, measure the conrod big end and the crank

pin widths individually to determine which one is to be

replaced.

Standard

0.17~0.32 mm

(0.007~0.013 in)

Service limit

0.50 mm

(0.020 in)

Conrod big end

side clearance

◉

CRANKSHAFT RUNOUT INSPEC-

TION

With the right and left crank journals supported with V-

block, turn the crankshaft slowly. At this time, measure

the crankshaft end runout using a dial gauge. If the

runout exceeds the service limit, replace the crankshaft.

Crankshaft runout

Service limit

0.05 mm (0.002 in)

◉

CRANKSHAFT REASSEBLY

Measure the width between the webs referring to the fi-

gure below when rebuilding the crankshaft.

Width between webs

Standard

96.9~97.1 mm

(3.815~3.823 in)

96.9~97.1mm

(3.815

~

3.823 in)

◉

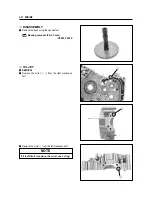

MAGNETO COVER

■

MAGNETO INSPECTION(Refer to page 6-4)

■

DISASSEMBLY

●

Remove the stator

①.

Magnetic stand : 09900-20701

Dial gauge : 09900-20606

V-block : 09900-21304

①

Содержание GT 650

Страница 5: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Страница 13: ...1 7 GENERAL INFORMATION EXTERIOR ILLUSTRATION ...

Страница 102: ...CARBURETOR 4 3 FUEL SYSTEM ...

Страница 138: ...LAMP HEADLAMP TURN SIGNAL LAMP TAIL BRAKE LAMP ELECTRICAL SYSTEM 6 16 ...

Страница 158: ...7 15 CHASSIS FRONT FORK ...

Страница 210: ...Prepared by HYOSUNG MOTORS MACHINERY INC 2nd Ed JUN 2004 Manual No 99000 94810 Printed in Korea ...