GR FS9040026000000000

GR FS9040025000000000

Maintenance

confidential

D.3.9

4

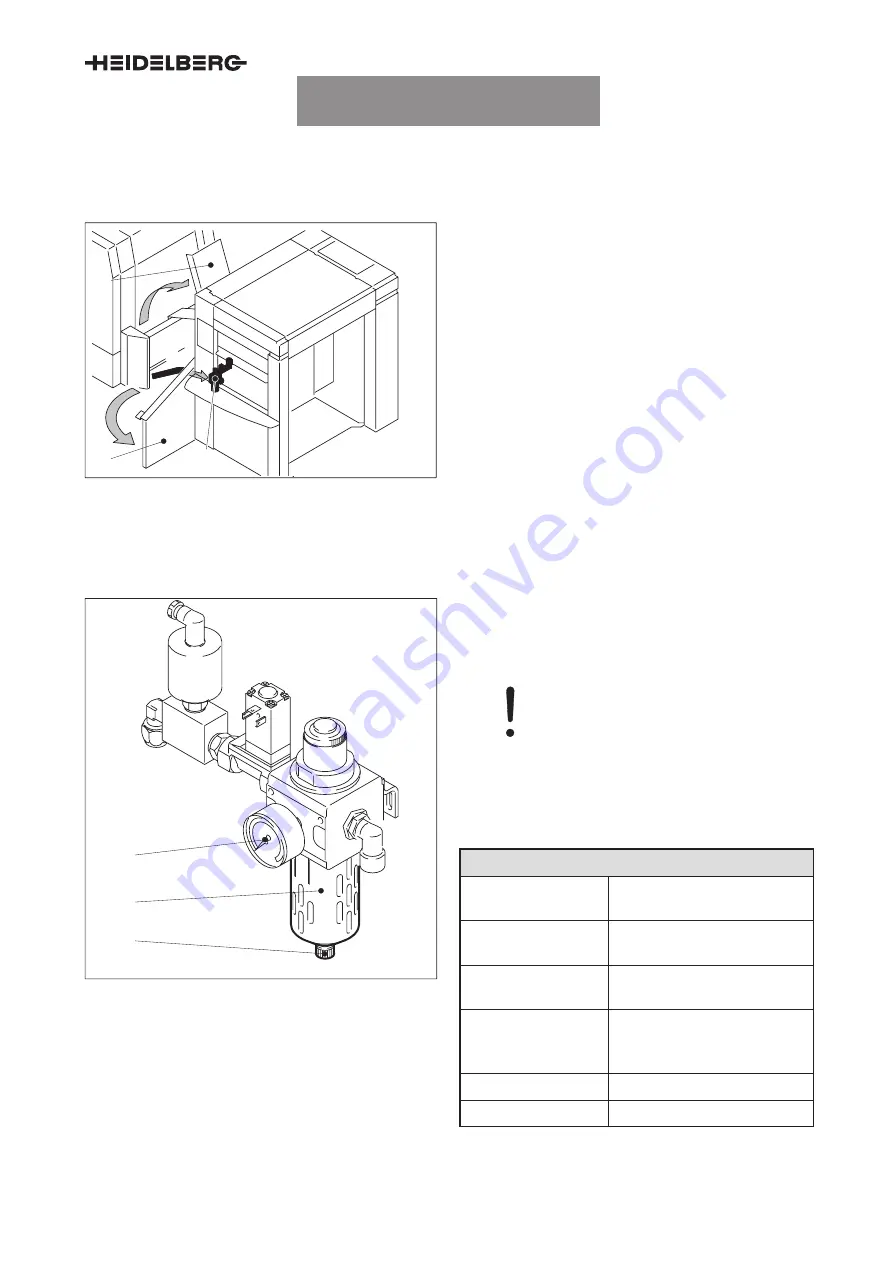

Service activities on the compressed-air control unit

4.1

Compressed-air control unit

3

1

2

Fig. 8

Location of the compressed-air control

unit

Place of installation

1

Feeder table

2

”Feeder” guard

3

Compressed-air control unit

The compressed-air control unit is installed on O.S.

underneath the feed table.

4.1.1

Compressed-air control unit – checking and, if necessary, the condensate

1

3

2

Fig. 9

Compressed-air control unit

1

Manometer

2

Glass cylinder

3

Drain plug

Caution –

The glass cylinder of the compressed-

air control unit (Fig. 9/1) must never be

filled completely with condensation wa-

ter. The condensation water may enter

in the pneumatic system and destroy

the pneumatic valves and pneumatic

cylinders.

Maintenance point description

Maintenance inter-

val

750 000 prints, or every

week

Maintenance loca-

tion

O.S.

Accessibility of lubri-

cating points

Open the ”feeder” guard.

Fold up the feed table.

Number/type/main-

tenance work

Check the compressed-air

control unit for condensation

water. Drain it if necessary.

Tool

–

Lubricant

–

Tab. 6

UTKFS9040003000000000

UTKFS9040003000000000003

Содержание Speedmaster CD 102

Страница 6: ...Main chapter overview A 2...

Страница 20: ...Main chapter overview B 2...

Страница 114: ...Preset Plus Feeder confidential C 1 76...

Страница 118: ...Main chapter overview D 4...

Страница 120: ...Chapter overview D 1 2...

Страница 134: ...General information confidential D 1 16...

Страница 136: ...Chapter overview D 2 2...

Страница 146: ...Chapter overview D 3 2...

Страница 166: ...Maintenance confidential D 3 22...

Страница 170: ...Index E 4 V VISCOGEN KL 300 Lubricant of the central grease lubrication D 1 10 W Washing fluid D 1 14...