31

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

M

a

INT

e

N

a

NC

e

Gas Fired Boiler

30

Harsco Industrial, Patterson-Kelley Technical Service 1.877.728.5351

M

a

INT

e

N

a

NC

e

Gas Fired Boiler

1. When the Boiler On/Off switch is turned on, power is provided through a circuit

breaker to the boiler control and the combustion blower.

2. If the high gas, low gas or low water level control is open, the boiler control

locks out and displays an error.

3. When the water temperature is below the boiler control setpoint minus the

hysteresis (On Differential), a heat request is generated.

4. Provided all limits are made, the boiler will attempt to start.

5. The controller checks that the air pressure switch is open indicating no airflow.

The blower is driven towards the prestart fan speed. When the air pressure

switch closes, the 25 second pre-purge time is started. After the pre-purge, the

blower is driven to the ignition speed.

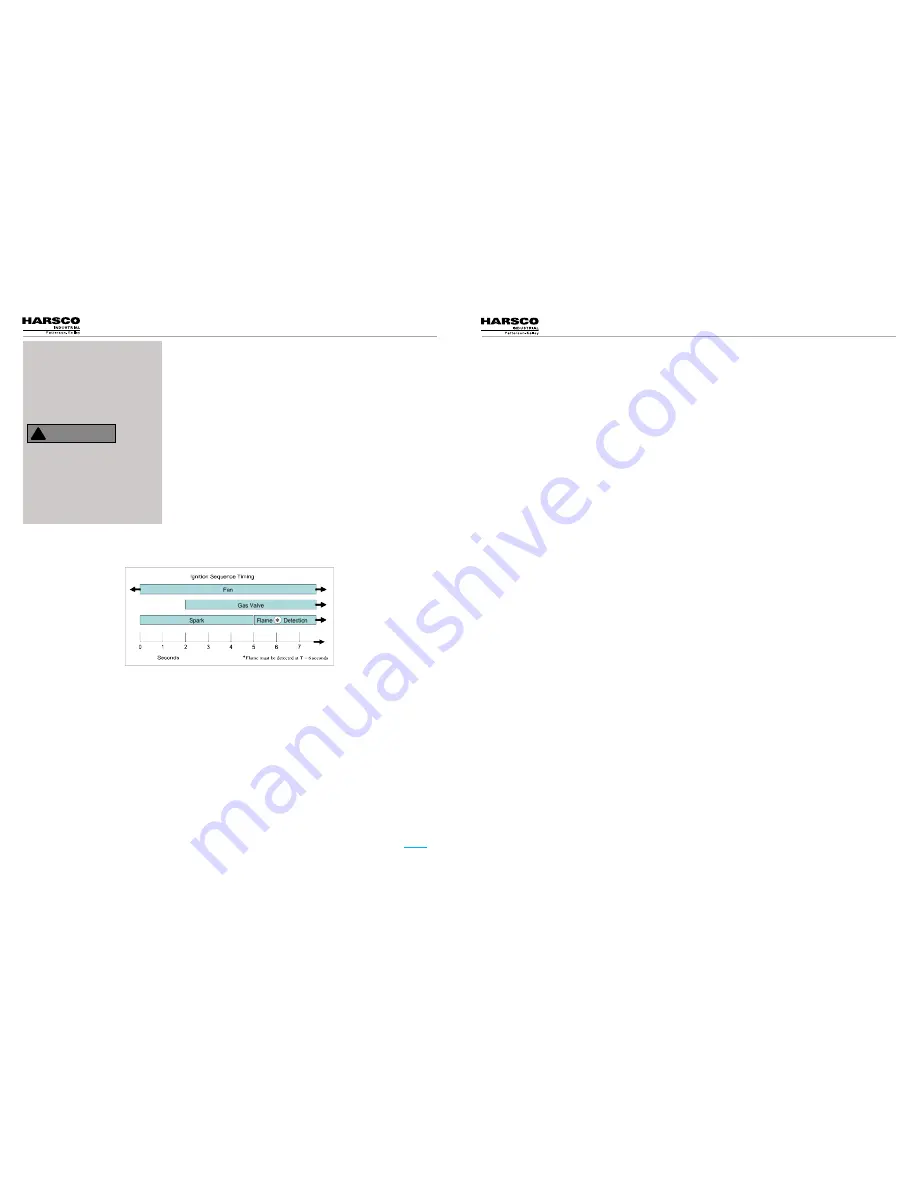

6. A trial for ignition begins. The sequence of events is illustrated graphically

below.

7. After ignition, the fan may be driven to low fire before the boiler is released to

modulation.

8. The control modulates the firing rate between low and high fire to maintain the

desired outlet water temperature.

9. The burner will continue firing until the outlet water temperature reaches set point plus hysteresis (Off Differential). At this

temperature the fuel supply is shut off and the combustion air fan continues to run for a 30 second post-purge.

10. When the water temperature is reduced by the load on the system, a heat request is generated. The operating sequence

will recycle to

Step 4

.

The ENVI® boiler control will display text based error descriptions to indicate any problems with the boiler. There

are two types of lockouts the control may experience: manual reset lockouts requiring an operator to press the

reset button, and automatic reset lockouts that will self reset when the error condition clears. A listing of errors

and their service codes is included at the end of this section.

Should the unit fail to operate, call a qualified service technician to troubleshoot the problem and implement

corrective actions.

5.6.1 loss of Power

In the event of a power failure, the display panel is not illuminated and the entire system is de-energized, closing

all automatic valves and halting all boiler operations. When power is restored the sequence of operation will

resume at

Step 4

. If any error/lockout is present when the power is lost, the control will retain that error/lockout

and display the error/lockout when the power is restored.

5.6.2 Loss of Water Level

The low water switch opens when there is insufficient water level in the boiler. Lockout

LOW WATER LEVEL

is

shown on the display, the burner operation is interrupted, and the boiler locks out. When the correct water level is

re-established, and the control reset button is pressed, the boiler will reset and will start the sequence at

Step 4

.

5.5 s

eQuenCe

of

o

peraTIon

n

oTICe

!

Once the boiler begins the ignition

sequence, the firing sequence will

continue until main flame is reached

regardless of heat request. The

sequence can be interrupted by

turning the power switch off.

If any “Manual Reset” limit device

trips,

DO NOT

reset without

determining and correcting the

cause. Manual Reset Limits

include: Flame safeguard, high or

low gas pressure, high temperature

limit, stack temperature, low water

level.

!

WARNING

5.6 T

roubleshooTIng

5.6.3 low Gas Pressure

The low gas pressure switch opens when there is (or has been) insufficient gas pressure available for proper

operation of the boiler. If an external gas-supply shut-off valve is closed for any reason, a low gas condition will

result. Locking

LOW GAS PRESSURE

is shown on the display, the burner operation is interrupted, and the boiler

locks out. When proper gas pressure is restored, and the control reset button is pressed, the boiler will reset and

will start the sequence at

Step 4

.

5.6.4 high Gas Pressure

The high gas pressure switch opens when there is (or has been) excessive gas pressure for the proper operation

of the boiler Locking

HIGH GAS PRESSURE

is shown on the display, the burner operation is interrupted, and the

boiler locks out. When proper gas pressure is restored, and the control reset button is pressed, the boiler will

reset and will start the sequence at

Step 4

.

5.6.5 high Water temperature

When the boiler water has exceeded both the operating and high-limit temperature the high limit switch

opens, and Locking

HIGH LIMIT

is shown on the display. When the water temperature falls below the high-limit

temperature, the boiler will remain locked out until the water high limit switch is manually reset and the front panel

reset button is pressed. Once reset, the control will restart the sequence of operation at

Step 4

.

5.6.6 low Air

If the display panel indicates Locking

AIR SWITCH NOT OPEN

or Locking

AIR SWITCH NOT CLOSED

this indicates

improper airflow through the boiler. Check the hoses leading to the air switches. Verify proper blower operation.

An air switch error does not necessarily mean that the air switch is defective.

When

AIR SWITCH NOT OPEN

is shown on the display, check that the air switch is open when the fan is off.

Check that there is no air flow through the boiler when the fan is off.

When

AIR SWITCH NOT CLOSED

is shown on the display, check that the air switch is closed when the fan is

running. If the air switch does not close within 5 minutes during purge, the boiler locks out. Check that the burner

is clean ("Cleaning the Burner,"

Section 5.2

) and that there are no obstructions to airflow in the intake or exhaust

ducts.

5.6.7 Flame Failure

In the event of a flame failure, the main fuel valves are de-energized and a manual reset lockout occurs. Locking

IGNITION FAILURE

or Lockout

FLAME FAILURE

is shown on the display. The cause of flame failure must be

diagnosed and repaired before the control is reset.

When

IGNITION FAILURE

is shown on the display, the boiler did not light during a trial for ignition. Check that the

spark, electrode, ignition wire, and gas valve are functioning properly.

When

FLAME FAILURE

is shown on the display, the boiler lost the flame during run. Check that the combustion is

setup properly, the gas pressure is correct, as well as other combustion parameters.

5.6.8 Flame error

Locking

LATE FLAME

Blocking

FALSE FLAME

These errors signify flame error. This may be caused by a failed or leaky gas valve or a flame detector

malfunction. If gas valve leakage is suspected, the unit must be isolated by turning off the main gas supply line.

Qualified and knowledgeable service personnel must be called to evaluate and repair/replace the failed parts.

5.6.9 stack Problem

BLOCKED FLUE

indicates that the high exhaust back pressure switch has tripped. This may be caused by a

blocked stack, a blocked air inlet, or a blocked condensate system. When the blockage is removed, the boiler will

automatically restart.

Figure 5.5