8

Hangar 9 F4U-1D Corsair 50 ARF

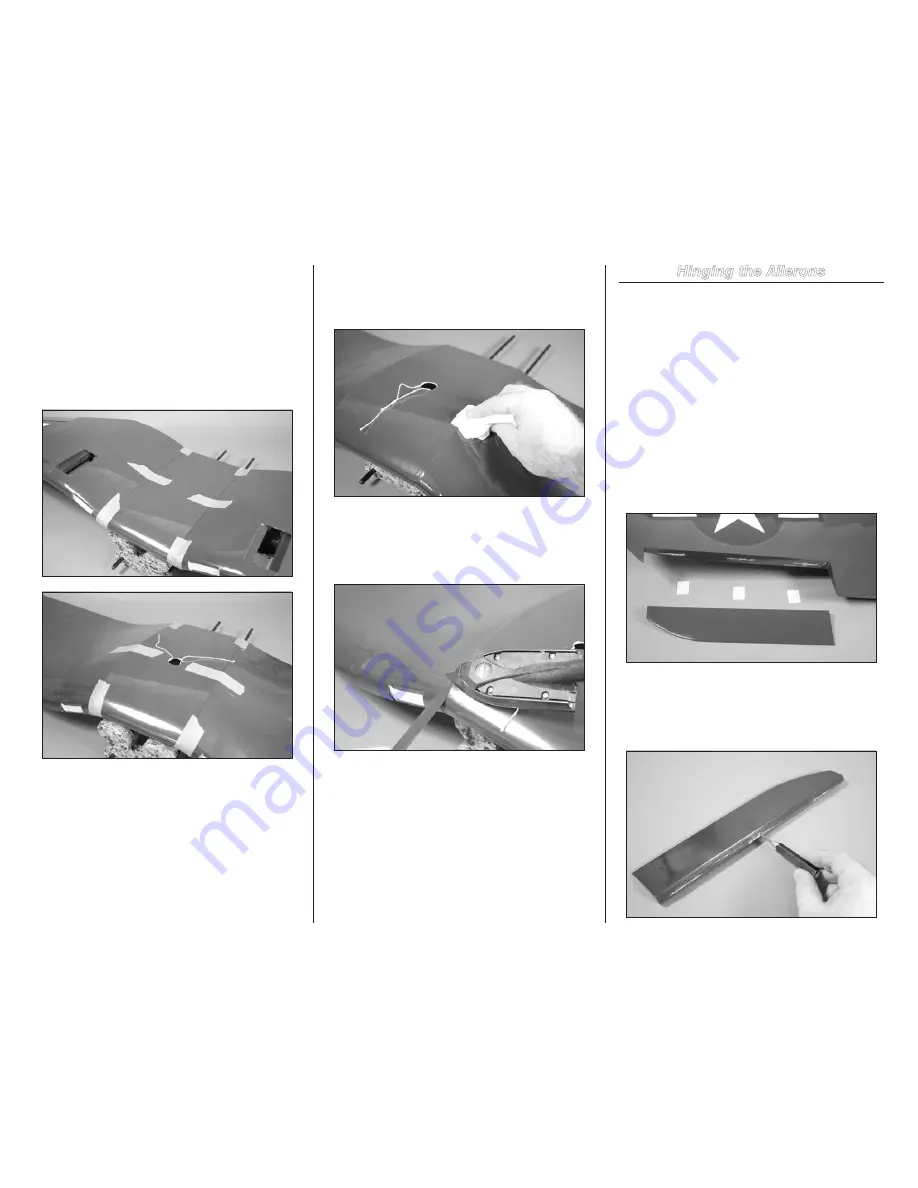

10. Slide the outer and center panels together. Make sure

to guide the strings in the wing panels through the hole in

the center panel. Wrap a piece of low-tack tape around the

leading and trailing edges to keep the panels in alignment.

Use a piece of low-tack tape to hold the panels tightly

together until the epoxy fully cures.

Note

: Make sure to support the wing at the center

section. If it is resting on the tips, it may change the

alignment of the panels while the epoxy cures.

hint

: Use low-tack tape to tape the string

to the top of the wing to prevent it from

falling back into the center section.

11. After the epoxy has been allowed to cure for an

hour, remove the tape from the wing panels. Use denatured

alcohol to remove any excess epoxy from the wing panels

before it has a chance to fully cure.

12. Use a covering iron to apply the two strips of

covering over the joint between the outer panels and the

center panel starting at the trailing edge and wrapping the

covering strip around the leading edge in one piece. This will

eliminate any seams which could come loose in flight.

hinging the Ailerons

Required Parts

Assembled wing

CA hinge (6)

Required Tools and Adhesives

Pin vise

Drill bit: 1/16-inch (1.5mm)

Thin CA

T-pins

Note

: The aileron bas been positioned on the

wing for shipping. Please follow the instructions

for gluing the hinges. Not following this procedure

will result in a poorly installed hinge, which could

cause the aileron to come loose in flight.

1. Separate the aileron from the wing. Set the three

hinges aside at this time.

2. Use a pin vise and 1/16-inch (1.5mm) drill bit to

drill a hole in the center of each hinge slot. This creates

a tunnel for the CA to wick into, creating a better bond

between the hinge and surrounding wood. Prepare both the

slots in the aileron and wing at this time.