30

Hangar 9 F4U-1D Corsair 50 ARF

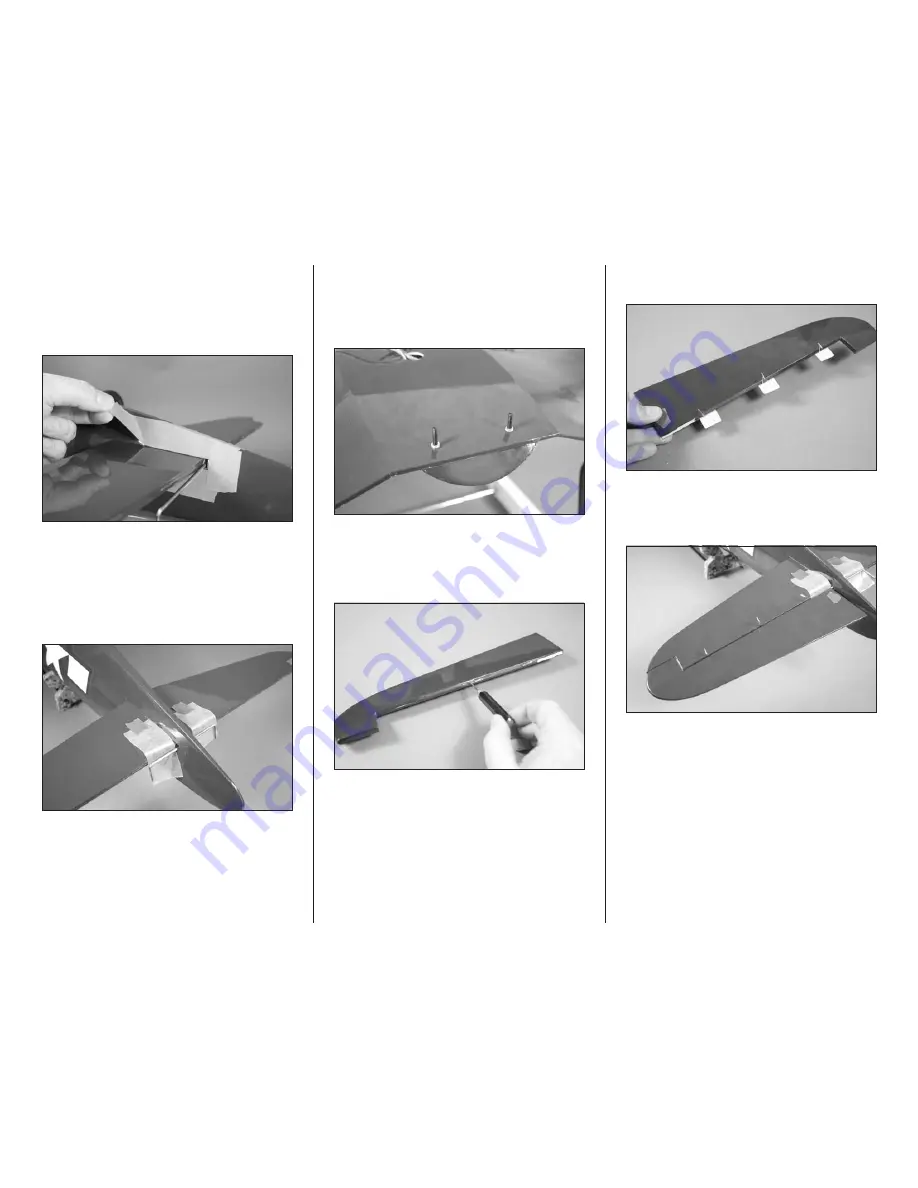

17. After around 25 minutes, before the epoxy fully cures,

carefully remove the tape from around the stabilizer. Pull the

tape away from the fuselage, being careful not to disturb the

position of the stabilizer. This will allow the epoxy to flow out

slightly, leaving a fillet between the fuselage and stabilizer.

Allow the epoxy to fully cure before disturbing the airframe.

18. Once the epoxy fully cures, the wing can be removed

from the fuselage by removing the two 8-32 bolts using a

9/64-inch hex wrench.

19. Cut two 1

1

/

2

-inch (38mm) wide pieces of waxed

paper. Tape the waxed paper to the stabilizer so the joiner

wire doesn’t get accidentally glued to the stabilizer when the

elevators are installed.

Note

: Once the epoxy has fully cured, the wing can

be removed from the fuselage using a 9/64-inch hex

wrench. Using small 1/4-inch (6mm) pieces of the

included safety tubing on the shaft of the 8-32 wing

bolts will help to keep the bolts with the wing.

20. Use a pin vise and 1/16-inch (1.5mm) drill bit to drill

a hole in the center of each hinge slot. This creates a tunnel

for the CA to wick into, creating a better bond between the

hinge and surrounding wood. Drill holes in both the elevator

and stabilizer hinge slots.

21. Place a T-pin in the center of three hinges. Insert

the hinges into the elevator as shown.

22. Check the fit of the elevator to the stabilizer. Make

sure the joiner wire is inserted into the elevator in the same

orientation as step 11. The elevator should fit tightly against

the stabilizer.