36

Hangar 9 F4U-1D Corsair 50 ARF

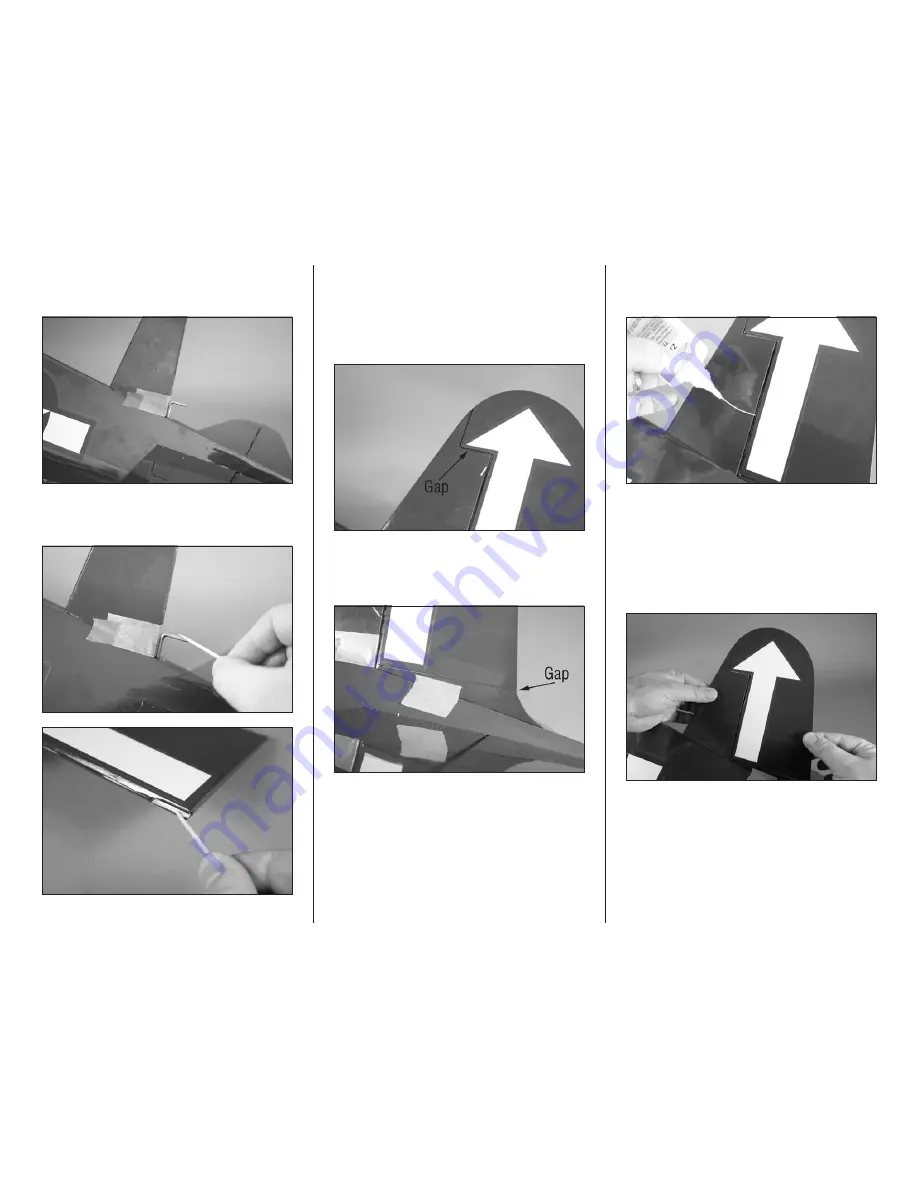

23. Cut a 1-inch (25mm) wide pieces of waxed paper.

Tape the waxed paper to the fin so the torque rod doesn’t get

accidentally glued to the fin when the rudder is installed.

24. Mix a small amount of 30-minute epoxy and apply

it to the torque rod and into the hole and slot in the rudder

using a toothpick.

25. Place the rudder into position using the hinges. Make

sure the torque rod fits into the hole in the rudder.

26. Position the rudder so there is a slight gap between

the balance tab and the top of the fin. This will set the gap so

the rudder can move smoothly. As well, set the clearance for

the balsa fairing.

27. Use low-tack tape to tape the balsa fairing in position

on the fuselage. Make sure the rudder can move freely and

not rub against the fairing before gluing the hinges. The gap

in step 26 should match the gap in this step.

28. Remove the tape and waxed paper from the fin.

Saturate each of the two hinges on both the top and bottom

of the hinge. Set the assembly aside to cure.

Important

: Allow the CA to cure WITHOUT using

CA accelerator. This is necessary to allow the CA

to soak into the hinge, creating the best bond

between the hinge and surrounding wood.

29. Once the CA has cured, check that all the hinges are

secure by gently trying to separate the rudder from the fin. If

any hinges are loose, re-apply CA to the loose hinges.