Model G0699 (Mfd. Since 5/15)

-71-

Symptom

Possible Cause

Possible Solution

Machine has vibration or noisy

operation.

1. Motor or component is loose.

2. Blade is at fault.

3. Belt(s) worn or loose.

4. Pulley is loose.

5. Motor mount loose/broken.

6. Machine is sits unevenly.

7. Arbor pulley is loose.

8. Motor fan is rubbing on fan cover.

9. Arbor bearings are at fault.

10. Motor bearings are at fault.

1. Inspect/replace stripped or damaged bolts/

nuts, and re-tighten with thread locking fluid.

2. Replace warped, bent, or twisted blade;

resharpen dull blade.

3. Re-tension (see

Page 72). Replace is

necessary.

4. Realign/replace shaft, pulley, setscrew, and

key as required.

5. Tighten/replace.

6. Relocate/shim machine.

7. Retighten/replace arbor pulley with shaft and

thread locking liquid.

8. Reposition fan cover; replace if damaged;

replace loose/damaged fan.

9. Replace arbor housing bearings; replace

arbor.

10. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

Main blade runs

counterclockwise.

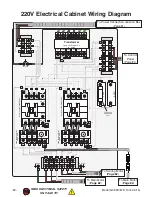

1. Two of the incoming power wires are

reversed.

1. Swap any two hot wires in the main power

junction box (

Page 15).

Operation

Symptom

Possible Cause

Possible Solution

Workpiece has burned edges,

binds, or kicks back.

1. Sliding table or rip fence is not

parallel to blade.

2. Riving knife is not aligned with the

blade.

3. Blade is warped or damaged.

1. Make sliding table or rip fence parallel to the

blade (

Pages 74 & 78).

2. Align riving knife with main blade (

Page 48).

3. Replace the blade.

Workpiece has chip out on the

bottom edge.

1. Scoring blade kerf does not match

the main blade.

1. Properly adjust the scoring blade to the main

blade (

Page 53).

Sliding table saw does not cut

square.

1. Sliding table is not parallel to blade.

2. Rip fence is not parallel to blade.

3. Crosscut fence is not perpendicular

to the blade.

1. Make sliding table parallel to the

blade (

Page 74).

2. Adjust the rip fence parallel to blade (

Page

29).

3. Adjust the 90° stop bolts so that the fence is

perpendicular to the blade (

Page 76).

Rip fence hits table top when

sliding across table.

1. Rip fence rail is too low.

2. Rip fence roller is too low.

1. Raise the rip fence rail (

Page 78).

2. Adjust the rip fence roller (

Page 78).

Blade does not reach 90˚, or

blade does not reach 45˚.

1. Blade stop bolts are out of

adjustment.

1. Adjust the stop bolts (

Page 73).

The rip fence scale is not

accurate.

1. The rip fence scale is out of calibration

or was not set up correctly.

1. Adjust the rip fence scale (

Page 78).

Tilt or elevation handwheels

difficult to turn.

1. Lock knob is tight.

2. Gears caked with dust.

1. Release the lock knob.

2. Clean out dust and grease the gears.

Содержание G0699

Страница 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Страница 108: ......