Model G0699 (Mfd. Since 5/15)

-65-

7. Make a lip from scrap wood that is approxi-

mately 2

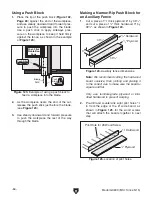

1

⁄

2

x

3

⁄

8

" x

3

⁄

8

", then fasten this piece

to the bottom of the base, as shown in

Figure

128.

Tip: Try using cyanoacrylate type wood glue

or small wood screws to secure the lip to the

push block base.

Using the Auxiliary Fence and Push

Block

1. Place the auxiliary fence on the table and

clamp it to the fence at both ends, then adjust

the distance between the auxiliary fence and

the blade—this determines how wide the

workpiece will be ripped (see the example in

Figure 129).

Workpiece

Cutting Width

Blade

Auxilliary Fence

Figure 129. Example of adjusting ripping

distance between blade and auxiliary fence.

3. Fasten the 6" and 3" wide boards with eight

#6 x

1

⁄

4

" wood screws through the holes you

drilled in

Step 2; the fence should look like

the one shown in

Figure 126.

4. Cut a piece of plywood 15" long and 5

1

⁄

4

" wide

for the base of a push block, then cut off a

strip

3

⁄

8

" wide by 12

1

⁄

2

" long (see

Figure 127).

3

⁄

4

"

Plywood

Completed

Fence

3

⁄

4

"

Hardwood

#8 x 1

1

⁄

2

"

Wood Screw

Figure 126. Auxiliary fence complete.

5

5

/

8

"

15"

5

1

/

4

"

12

1

/

2

"

2

1

/

2

"

3

/

8

"

Figure 127. Push block base pattern.

5. Cut a piece of

1

⁄

2

" plywood 10" long by 5"–9"

high for the handle, then cut it to the desired

final shape.

6. Pre-drill and countersink three holes through

the bottom center of the base, then attach the

handle to the base with #6 x

1

⁄

4

" wood screws

(see

Figure 128).

Lip

Handle

3

/

8

"

3

/

8

"

2

1

/

2

"

Figure 128. Push block and lip.

Keep the riving knife and blade guard prop-

erly installed during cutting operations.

Failure to do this present amputation

hazards!

Содержание G0699

Страница 21: ...Model G0699 Mfd Since 5 15 19 5mm Hardware Recognition Chart...

Страница 108: ......