❏

5. Cut or drill clearance holes in the firewall for the heads

of the bolts that hold the engine to the mount plate, then

mount the plate to the firewall with four more 1/4-20 x 3/4"

[19mm] bolts, washers and 1/4-20 blind nuts included with

this kit. When mounted to the engine, the backplate of the

spinner should be 6-1/2" [165mm] from the firewall.

❏

6. Pin the firewall to the fuselage by performing steps

6 and 7.

MOUNTING A FUJI BT-50SB GAS ENGINE

These instructions show how to mount a Fuji BT-50SB engine.

The prop hub that comes with the engine must be exchanged

for a Fuji short prop hub (FJIG6754—sold separately). If

mounting a different gas engine, these instructions may be

used as a guide. The Fuji 50 with the short prop hub will

automatically have the correct spacing from the firewall, but if

mounting another engine, the back plate of the spinner should

be 6-1/2" [165mm] from the firewall.

❏

1. Use a straightedge and a pen to extend the horizontal and

vertical centerlines on the firewall all the way to the edges.

❏

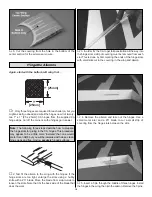

2. Cut the Fuji BT-50 engine mounting bolt pattern from

page 49. (If making a photo copy, be certain it comes out the

same size as the pattern and is not dimensionally distorted.)

Tape the pattern to the firewall aligning the lines on the pattern

with the lines on the firewall. Use a large T-pin to mark the

center of the engine mounting holes onto the firewall.

❏

3. Remove the pattern from the firewall. Drill 1/16"

[1.6mm] pilot holes at the marks. Enlarge the holes with a

19/64" [7.6mm] drill.

❏

4. Use large wire cutters, a metal file or a rotary tool with

a cutoff wheel to trim two 1/4-20 blind nuts so they will fit in

the top holes in the firewall without interfering with the top of

the engine box.

❏

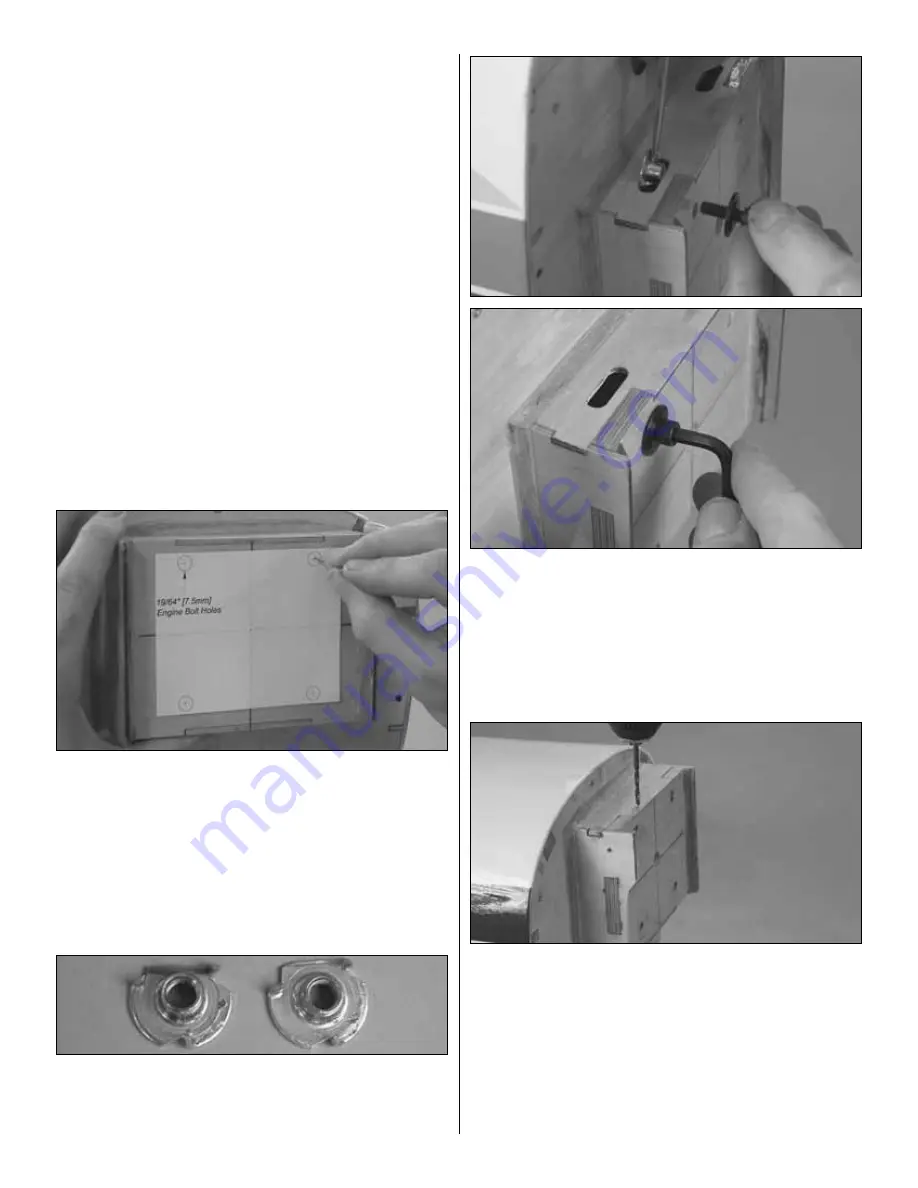

5. Apply a few dabs of epoxy to the flange of one of the

blind nuts. Use hemostats or needle nose pliers to hold the

nut to the back of the firewall while threading a 1/4-20 x 1"

[25mm] socket head cap screw (not included) with a large

1/4" [6.4mm] washer to the nut. Use a 3/16" [4.8mm] hex

wrench to tighten the screw fully, drawing the nut into the

back of the firewall. Install the remaining three blind nuts the

same way.

❏

6. Drill 1/8" [3.2mm] holes 3/4" [20mm] deep through the

top, bottom and both sides of the “box” that holds the

firewall. The holes should be centered over the sides of the

firewall and there should be at least two holes per side.

❏

7. Cut one of the supplied 1/8" x 10" [3.2 x 250mm] wood

dowels into as many 3/4" [20mm] pieces as holes were

drilled around the firewall. Use epoxy to glue the dowels into

the holes. Cut or sand the ends of the dowels even with the

engine box sides.

19