GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Keine Haftung für Druckfehler. Technische Änderungen vorbehalten! Liability for printing errors excluded. We reserve the right to introduce modifications. Sous réserve de modifica-

tions! Nous ne sommes pas responsables d’éventuelles erreurs d’impression!

11/2009

13

•

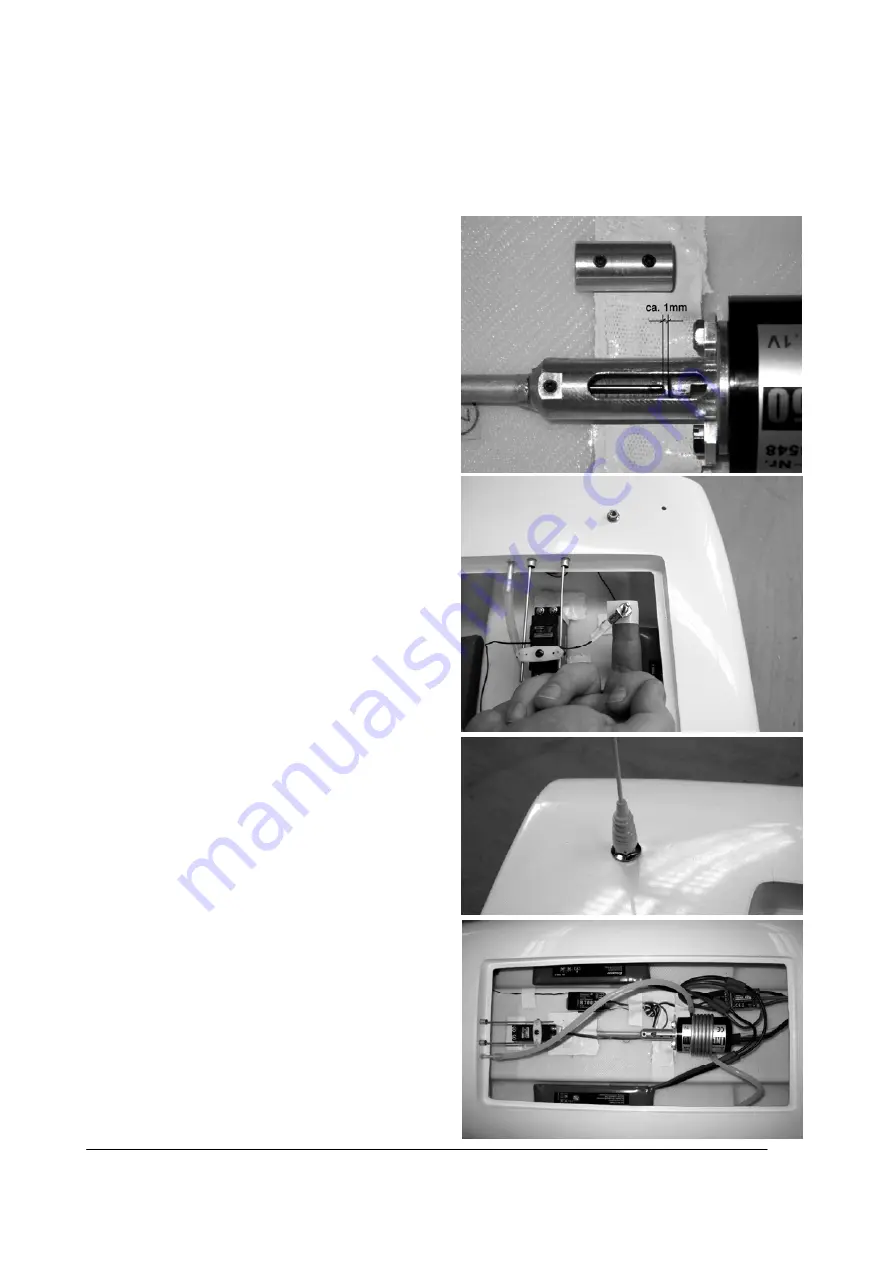

You may need to shorten the 2 mm Ø shaft to the point where there is only slight clearance between it

and the end of the motor shaft.

TIP:

the easiest method of cutting the spring steel shaft is to use a cut-

off disc from a Dremel multi-function set, e.g. Order No. D300-25.

•

Lubricate the shaft system using plenty of grease.

TIP:

if you use a tube of water-neutral grease (Order

No. 570), you can easily force it into the shaft strut after removing the shaft, then gently push the shaft

back into place using a constant rotary motion. De-grease the end of the shaft which is to fit in the cou-

pling before tightening the grubscrews in the shaft coupling.

TIP:

to achieve better mechanical power

transmission between the shafts and the cou-

pling, it is a good idea to file small flats in the

shafts. This provides a mechanical “key” for the

grubscrews, and prevents them slipping on the

shafts.

•

The following step is not necessary if you are

using an iFS system: drill a suitable hole for the

retaining screw of the steel whip aerial, and

mount the whip in the hull. Locate the flexible

wire aerial attached to the receiver, and shorten it

by the length of the whip. Strip the end of the

flexible wire aerial and connect it electrically to

the whip aerial, then deploy the remainder of the

flexible aerial neatly inside the boat, as far as

possible from all high-current cables, and secure

it with adhesive tape.

Adjusting the shaft strut on the model

The propeller is correctly adjusted when the rotational

axis of the shaft lies parallel to the surface of the water

when the boat is running at maximum speed. The

shaft strut is held in place by a single screw; always

tighten this screw firmly, as the propeller exerts a

powerful moment on the shaft strut and will try to

move it out of position.

TIP:

shifting it in the downward

direction raises the stern, while moving it upwards

lowers the stern.

TIP:

once you have established the

optimum setting for the shaft strut, we suggest that

you drill a through-hole and fit an M2 screw through it

to prevent the setting being lost accidentally.